APPENDIX 7 CABLE MANUFACTURING DRAWINGS

Appendix 7.5 F322 Cable Manufacturing Drawing

I - 90

Appendix 7.5 F322 Cable Manufacturing Drawing

Application :

Control unit - manual pulse generator connection

(When connecting three manual pulse generators)

Option (Compatible connector set)

FCUA-CS000 (Note that only the control

unit connector is compatible)

List of parts used

F322

Note (3)

1 2

3

4

Control

unit side

Manual pulse

generator side

F322

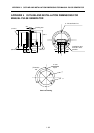

Assembly drawing

No. Part name/type Maker Q'ty

1

Connector

10120-3000VE

Sumitomo 3M 1

2

Connector case

10320-52F0-008

Sumitomo 3M 1

3

Wire material

UL1061-2464

AWG22

× 6P

Note (1)

(1)

4

Crimp terminal

V1.25-3

J. S. T 12

1HA

1HB

+12V

GND

2HA

2HB

+12V

GND

3HA

3HB

GND

Maximum cable length: 30m

Manual pulse

generator side

Control

unit side

4

14

6

1

1HA

1HB

+12V

3

13

16

5

7

17

11

Case GND plate

GND

2HA

2HB

+12V

GND

3HA

3HB

+12V

GND

Connection diagram

Manufacturing precautions

(1) The wire material shall be a shielded, 6-pair stranded cable equivalent to UL1061-2464

Standards AWG22 (0.3mm

2

).

(2) The parts used shall be Mitsubishi recommended parts. Equivalent parts may be used providing

they are compatible with the specifications.

(3) Attach the nameplate (with protective cover stamped with the cable name) in the position

designated in the assembly drawing.

(4) Fold the wire material shield on the control unit side over the sheath, and wrap copper foil tape

over it. Connect to the connector case GND plate.

(5) Stamp the name of each signal on the crimp terminal side mark tube and install.

(6) In the catalog specifications, the part 1 connector uses AWG24 (0.2mm

2

) or less wire material,

but AWG22 (0.3mm

2

) can also be used.