APPENDIX 7 CABLE MANUFACTURING DRAWINGS

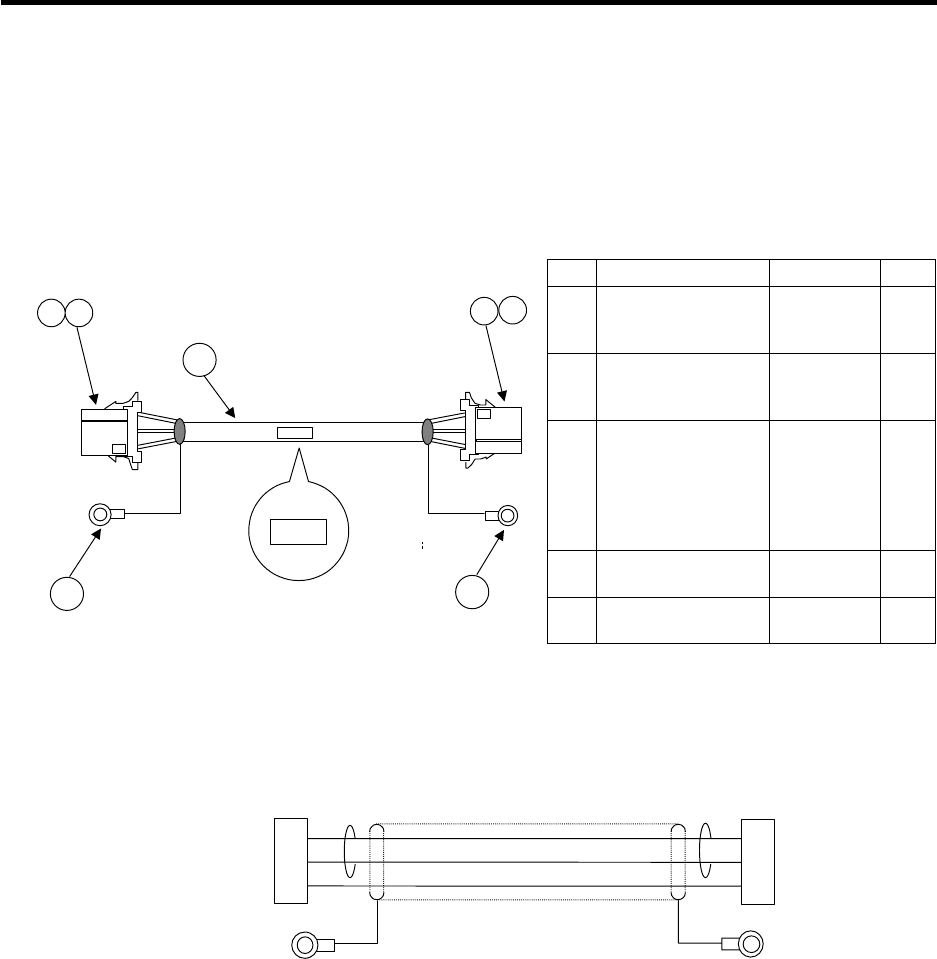

Appendix 7.14 FCUA-R211 Cable Manufacturing Drawing

I - 99

Appendix 7.14 FCUA-R211 Cable Manufacturing Drawing

Application:

Control unit – remote I/O unit connection

Remote I/O unit – remote I/O unit connection

Remote I/O unit – communication terminal connection

Option (Compatible connector set)

FCUA-CN211

(Note that when a one end connector

and contact are used, there is no

crimp terminal)

List of parts used

1

2

3

4

5

1

2

R211

X

X

R211

Control unit side

Note (3)

Assembly drawing

No. Part name/type Maker Qty.

1

Connector

1-178288-3

Tyco

Electronics

AMP

2

2

Contact

1-175218-2

Tyco

Electronics

AMP

6

3

Wire material

MIX3CHRV-SV-SB

Twisted pair cable

with compound

3-pair shield.

Note (1)

TOA

Electric

Industry

(1)

4

Crimp terminal

V1.25-3

J. S. T 1

5

Crimp terminal

V1.25-5

J. S. T 1

1

2

3

1

2

3

TXRX

TXRX*

LG

FG

Note (5)

TXRX

TXRX*

LG

FG

Maximum cable length: 50m

Connection diagram

Manufacturing precautions

(1) The wire material shall be a shielded 3-pair stranded pair cable equivalent to AWG20 (0.5mm

2

).

(2) The parts used shall be Mitsubishi recommended parts. Equivalent parts may be used providing

they are compatible with the specifications.

(3) Attach the nameplate (with protective cover stamped with the cable name) in the position

designated in the assembly drawing.

(4) Install each crimp terminal side after stamping the name of each signal on the mark tube.

(5) Protect both ends of the wire material with insulation bushing.

(6) Use AWG18 (0.75mm

2

) or equivalent for the shield treatment wire material.

(7) Ground the crimp terminal connected to the shield to the control unit or communication terminal

frame ground.

Note that there may be cases where only one end is connected, both ends are connected, or

neither end is connected to improve the noise resistance,.