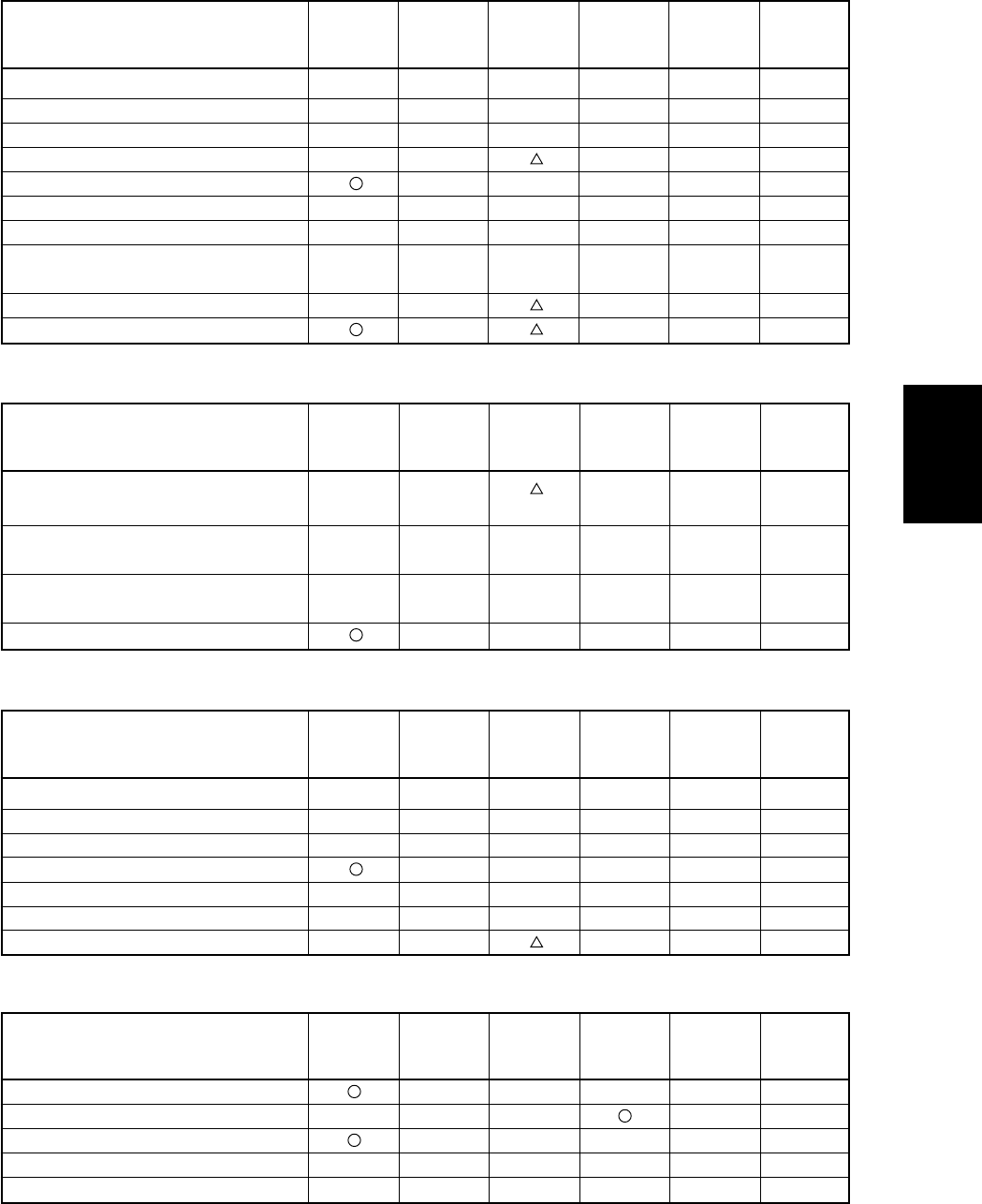

November 2003 © TOSHIBA TEC 4 - 9 e-STUDIO3511/4511 PREVENTIVE MAINTENANCE

D1. Transport roller (upper, middle and A

lower)

D2. One side of the GCB bushing to L

which the shaft is inserted

D3. One side of the plastic bushing W1

to which the shaft is inserted

D4. Paper guide W

E. Bypass feed unit

F. Main charger

E1. Pickup roller 80/80 P22-I26

E2. Feed roller 80/80 P22-I37

E3. Separation roller AV, W2 80/80 P21-I1 *e1

E4. Bypass tray

E5. Drive gear (shaft) W1

E6. GCB bushing bearing L

E7. Transport roller A

Items to check

F1. Main charger case

F2. Main charger wire

F3. Contact point of terminals

F4. Charger wire cleaning pad

F5. Main charger grid

D. Automatic duplexing unit

C. Feed unit

C1. Pickup roller 80/80 P18-I20

C2. Feed roller 80/80 P18-I24

C3. Separation roller AV, V2 80/80 P18-I5 *c1

C4. Transport roller A

C5 Paper guide

C6. Drive gear (tooth face and shaft) W1 *c2

C7. GCB bushing bearing L

C8. One side of the plastic bushing to W1

which the shaft is inserted

C9. Registration roller A

C10.Paper dust removal brush *c3

Replace-

Items to check Cleaning

Lubri-

ment

Operation Parts list

Remarks

cation

(KS)

check <P-I>

Replace-

Items to check Cleaning

Lubri-

ment

Operation Parts list

Remarks

cation

(KS)

check <P-I>

Replace-

Items to check Cleaning

Lubri-

ment

Operation Parts list

Remarks

cation

(KS)

check <P-I>

Cleaning

Replace-

ment

(KD)

160/200

160/200

160/200

Lubri-

cation

Operation

check

Parts list

<P-I>

P28-I15

P28-I12

P28-I21

Remarks

*f1

*f1

04/02