6

Installation of the inverter and enclosure

design

1.4 Installation of the inverter and enclosure design

When an inverter enclosure is to be designed and manufactured, heat generated by contained equipment, etc., the

environment of an operating place, and others must be fully considered to determine the enclosure structure, size and

equipment layout. The inverter unit uses many semiconductor devices. To ensure higher reliability and long period of

operation, operate the inverter in the ambient environment that completely satisfies the equipment specifications.

1.4.1 Inverter installation environment

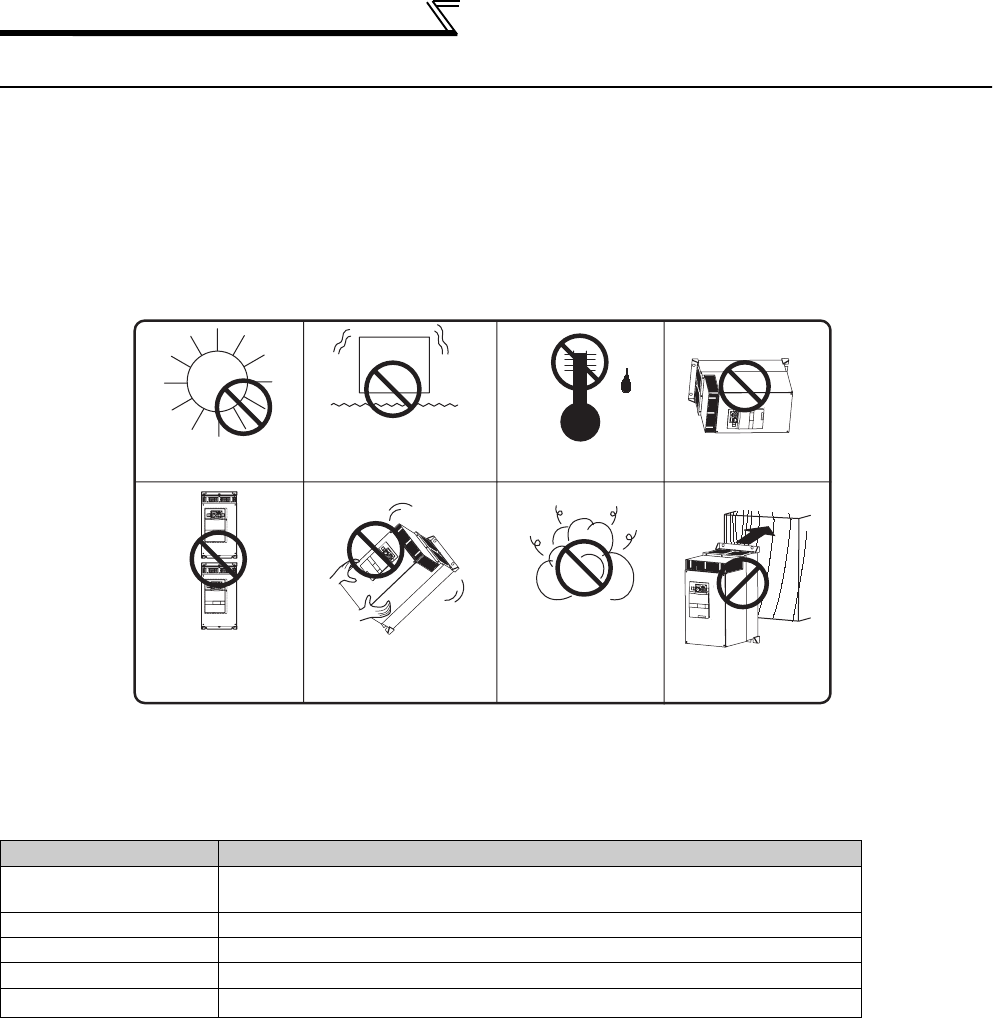

The inverter consists of precision mechanical and electronic parts. Never install or handle it in any of the following

conditions as doing so could cause an operation fault or failure.

As the inverter installation environment should satisfy the standard specifications indicated in the following table,

operation in any place that does not meet these conditions not only deteriorates the performance and life of the

inverter, but also causes a failure. Refer to the following points and take adequate measures.

Environmental standard specifications of inverter

Item Description

Surrounding air

temperature

-10°C to +50°C (non-freezing)

Ambient humidity 90% RH maximum (non-condensing)

Atmosphere Free from corrosive and explosive gases, dust and dirt

Maximum Altitude 1,000m or less

Vibration

5.9m/s

2

or less at 10 to 55Hz (directions of X, Y, Z axes)

Direct sunlight

High temperature,

high humidity

Horizontal placement

Mounting to

combustible material

Oil mist, flammable

gas, corrosive gas,

fluff, dust, etc.

Transportation by

holding the front cover

Vertical mounting

(When installing two or

more inverters, install

them in parallel.)

Vibration (5.9m/s

2

or more

at 10 to 55Hz (directions of

X, Y, Z axes))