135

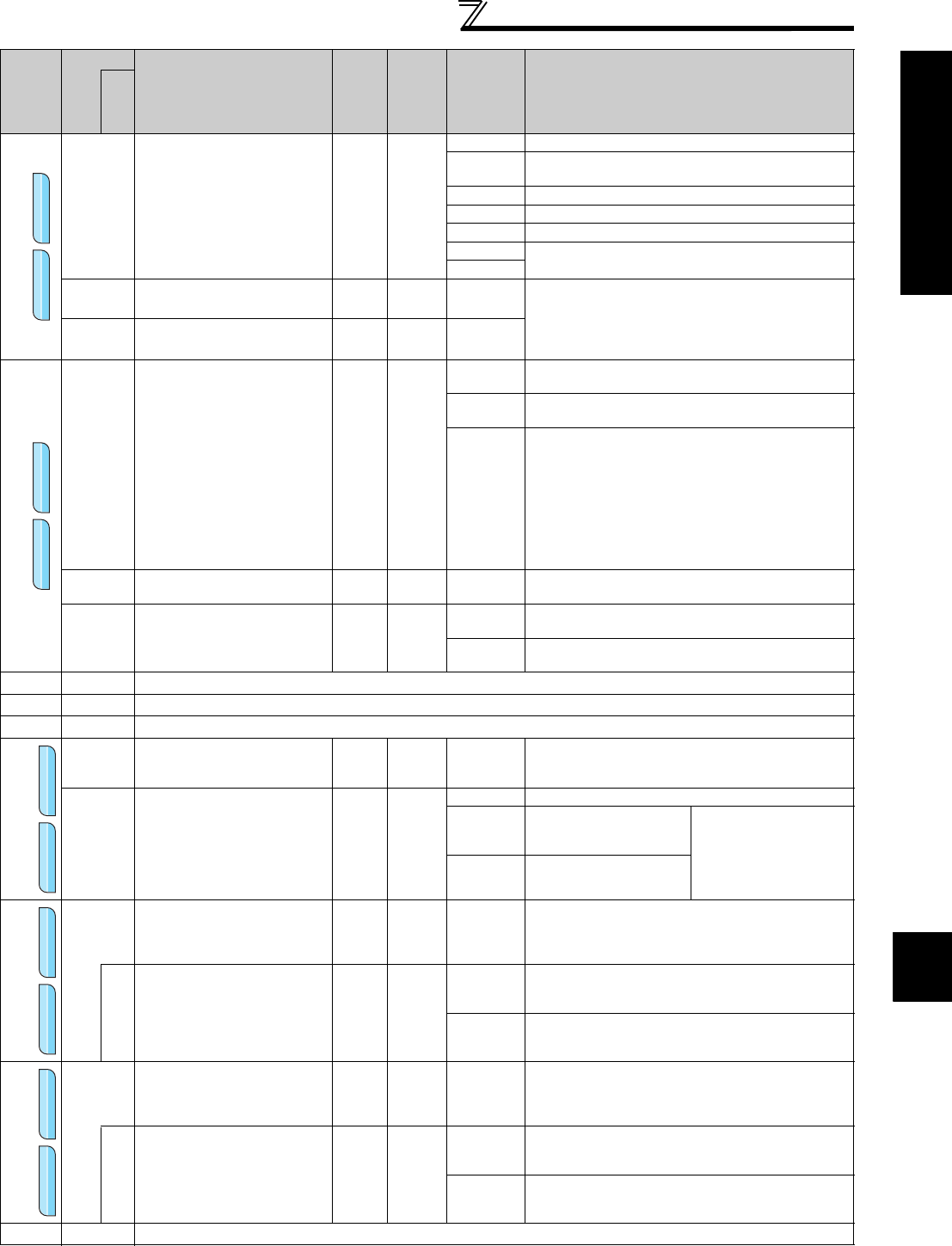

Parameter List

Parameter List

4

DRIVING THE MOTOR

Torque command source selection

804

Torque command source

selection

10

0 Torque command by terminal 1 analog input

1

Torque command by parameter

Pr.805 or Pr.806 setting (-400% to 400%)

2 Torque command using pulse train input (FR-A7AL)

3 Torque command by using CC-Link (FR-A7NC)

4 Digital input from the option (FR-A7AX)

5

Torque command by using CC-Link (FR-A7NC)

6

805

Torque command value

(RAM)

1% 1000%

600 to

1400%

Digital setting of the torque command can be made

by setting Pr. 805 or Pr. 806. (Setting from

communication option, etc. can be made.)

In this case, set the speed limit value to an

appropriate value to prevent overspeed.

806

Torque command value

(RAM,EEPROM)

1% 1000%

600 to

1400%

Speed limit

807

Speed limit selection

10

0

Use the speed command value during speed control

as speed limit.

1

According to Pr. 808 and Pr. 809, set the speed limit in

forward and reverse rotation directions individually.

2

The analog voltage of the terminal 1 input is used to

make speed limit. For 0 to 10V input, set the forward

rotation speed limit. (The reverse rotation speed limit

is Pr. 1 Maximum frequency)

For -10 to 0V input, set the reverse rotation speed

limit. (The forward rotation speed limit is Pr. 1

Maximum frequency.) The maximum frequency of both

the forward and reverse rotations is Pr. 1 Maximum

frequency.

808

Forward rotation speed limit

0.01Hz 60Hz 0 to 120Hz

Set the speed limit level during forward rotation.

(valid when Pr. 807 = 1)

809

Reverse rotation speed limit

0.01Hz 9999

0 to 120Hz

Set the speed limit level during reverse rotation.

(valid when Pr. 807 = 1)

9999

The setting is the same as that of the torque limit in

the forward rotation direction.

—

810

Refer to Pr. 22.

—

811

Refer to Pr. 22 and Pr. 37.

—

812 to 817

Refer to Pr. 22.

Easy gain

tuning selection

818

Easy gain tuning response

level setting

121 to 15

1 : Slow response

↓

15 : Fast response

819

Easy gain tuning selection

10

0 No tuning

1

With load estimation

(only under vector control)

The optimum gain is

automatically set from the

torque command and

speed during motor

operation.

2

Manual input of load (Pr.

880)

Speed loop proportional

gain setting

820

Speed control P gain 1

1% 60% 0 to 1000%

Set the proportional gain for speed control.

(Increasing the value improves trackability in

response to a speed command change and reduces

speed variation with disturbance.)

830

Speed control P gain 2

1% 9999

0 to 1000%

Second function of Pr. 820 (valid when RT signal is

on)

9999 No function

Speed control

integral time setting

821

Speed control integral time

1

0.001s 0.333s 0 to 20s

Set the integral time during speed control. (Decrease

the value to shorten the time taken for returning to

the original speed if speed variation with disturbance

occurs.)

831

Speed control integral time

2

0.001s 9999

0 to 20s

Second function of Pr. 821 (valid when the RT

terminal is on)

9999 No function

—

822

Refer to Pr. 74.

Func

t

ion

Parameter

Name

Incre

ments

Initial

Value

Range Description

Related

parameters

Sensorless

Sensorless

Sensorless Vector

Vector

VectorSensorless

Sensorless

Sensorless Vector

Vector

Vector

Sensorless

Sensorless

Sensorless Vector

Vector

VectorSensorless

Sensorless

Sensorless Vector

Vector

VectorSensorless

Sensorless

Sensorless Vector

Vector

Vector