164

Check first when you have a trouble

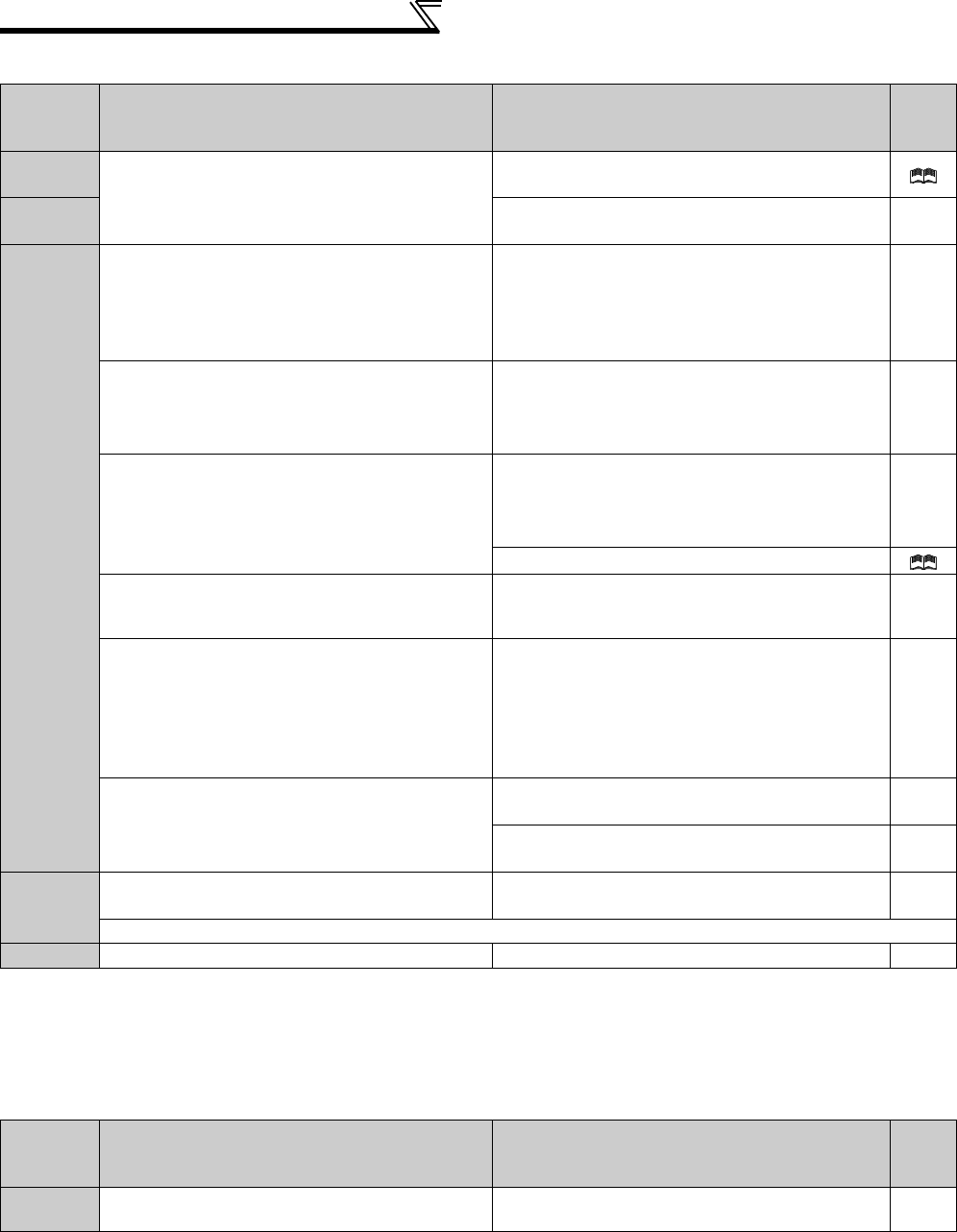

5.6.2 Motor or machine is making abnormal acoustic noise

5.6.3 Inverter generates abnormal noise

Larger acoustic noise is generated during regenerative driving than during power driving because the inverter contains

an AC reactor. This is not a fault.

Connecting a single-phase power supply device or having an unbalanced power supply may cause the reactor to

generate acoustic noise even in non-operating status. This is not a fault.

Check

points

Possible Cause Countermeasures

Refer

to

page

Input

signal

Disturbance due to EMI when frequency command

is given from analog input (terminal 1, 2, 4).

Take countermeasures against EMI.

Parameter

Setting

Increase the Pr. 74 Input filter time constant if steady

operation cannot be performed due to EMI.

114

Parameter

Setting

No carrier frequency noises (metallic noises) are

generated.

In the initial setting, Pr. 240 Soft-PWM operation

selection is enabled to change motor noise to an

unoffending complex tone. Therefore, no carrier

frequency noises (metallic noises) are generated.

Set Pr. 240 = "0" to disable this function.

113

Resonance occurs. (output frequency)

Set Pr. 31 to Pr. 36 (Frequency jump).

When it is desired to avoid resonance attributable to

the natural frequency of a mechanical system, these

parameters allow resonant frequencies to be jumped.

108

Resonance occurs. (carrier frequency)

Change Pr. 72 PWM frequency selection setting.

Changing the PWM carrier frequency produces an

effect on avoiding the resonance frequency of a

mechanical system or a motor.

113

Set a notch filter.

Auto tuning is not performed under Advanced

magnetic flux vector control, Real sensorless vector

control, or vector control.

Perform offline auto tuning. 71

Gain adjustment during PID control is insufficient.

To stabilize the measured value, change the

proportional band (Pr. 129) to a larger value, the

integral time (Pr. 130) to a slightly longer time, and the

differential time (Pr. 134) to a slightly shorter time.

Check the calibration of set point and measured

value.

120

The gain is too high under Real sensorless vector

control or vector control.

During speed control, check the setting of Pr. 820 (Pr.

830) speed control P gain.

135

During torque control, check the setting of Pr. 824 (Pr.

834) torque control P gain.

136

Others

Mechanical looseness

Adjust machine/equipment so that there is no

mechanical looseness.

—

Contact the motor manufacturer.

Motor

Operating with output phase loss Check the motor wiring. —

Check

points

Possible Cause Countermeasures

Refer

to

page

Fan

Fan cover was not correctly installed when a cooling

fan was replaced.

Install a fan cover correctly. 175