81

Before operation

4

DRIVING THE MOTOR

(6) Troubleshooting (speed)

Phenomenon Cause Countermeasures

1

Motor does not rotate.

(Vector control)

(1) The motor wiring is wrong (1) Wiring check

Select V/F control (set "9999" in Pr. 80 or Pr. 81 ) and

check the rotation direction of the motor.

For the SF-V5RU (1500r/min series), set "160V

(320V)" in Pr. 19 Base frequency voltage, and set "50Hz"

in Pr. 3 Base frequency.

When the forward rotation signal is input,

the motor running in the counterclockwise

direction as viewed from the motor shaft is

normal. (If it runs in the clockwise direction,

the phase sequence of the inverter output

side wiring is incorrect.)

(2) Encoder specifications (encoder

specification selection switch

FR-A7AP/FR-A7AL (option)) are

wrong

(2) Check the encoder specifications.

Check the encoder specifications selection switch

(FR-A7AP/FR-A7AL (option)) of differential/

complementary

(3) The encoder wiring is wrong. (3) Check that FWD is displayed when running the motor

in the counter-clockwise direction from outside during

a stop of the inverter with vector control setting.

If REV is displayed, the encoder phase sequence is

wrong.

Perform the correct wiring or match the Pr. 359 Encoder

rotation direction.

(4) The Pr. 369 Number of encoder

pulses setting and the number of

encoder used are different.

(4) The motor will not run if the parameter setting is

smaller than the number of encoder pulses used. Set

the Pr. 369 Number of encoder pulses correctly.

(5) Encoder power specifications

are wrong. Or, power is not input.

(5) Check the power specifications (5V/12V/15V/24V) of

encoder and input the external power supply.

2

Motor does not run at

correct speed. (Speed

command does not match

actual speed)

(1) The speed command from the

command device is incorrect.

The speed command is

compounded with noise.

(1) Check that a correct speed command comes from the

command device.

Decrease Pr. 72 PWM frequency selection.

(2) The speed command value

does not match the inverter-

recognized value.

(2) Readjust speed command bias/gain Pr. 125, Pr. 126, C2

to C7 and C12 to C15.

(3) The number of encoder pulses

setting is incorrect.

(3) Check the setting of Pr. 369 Number of encoder pulses.

(vector control)

3

Speed does not rise to the

speed command.

(1) Insufficient torque.

Torque limit is actuated.

(1) -1 Increase the torque limit value.

(Refer to torque limit of speed control on Chapter 4

of the Instruction Manual (Applied) )

(1) -2 Insufficient capacity

(2) Only P (proportional) control is

selected.

(2) When the load is heavy, speed deviation will occur

under P (proportional) control. Select PI control.

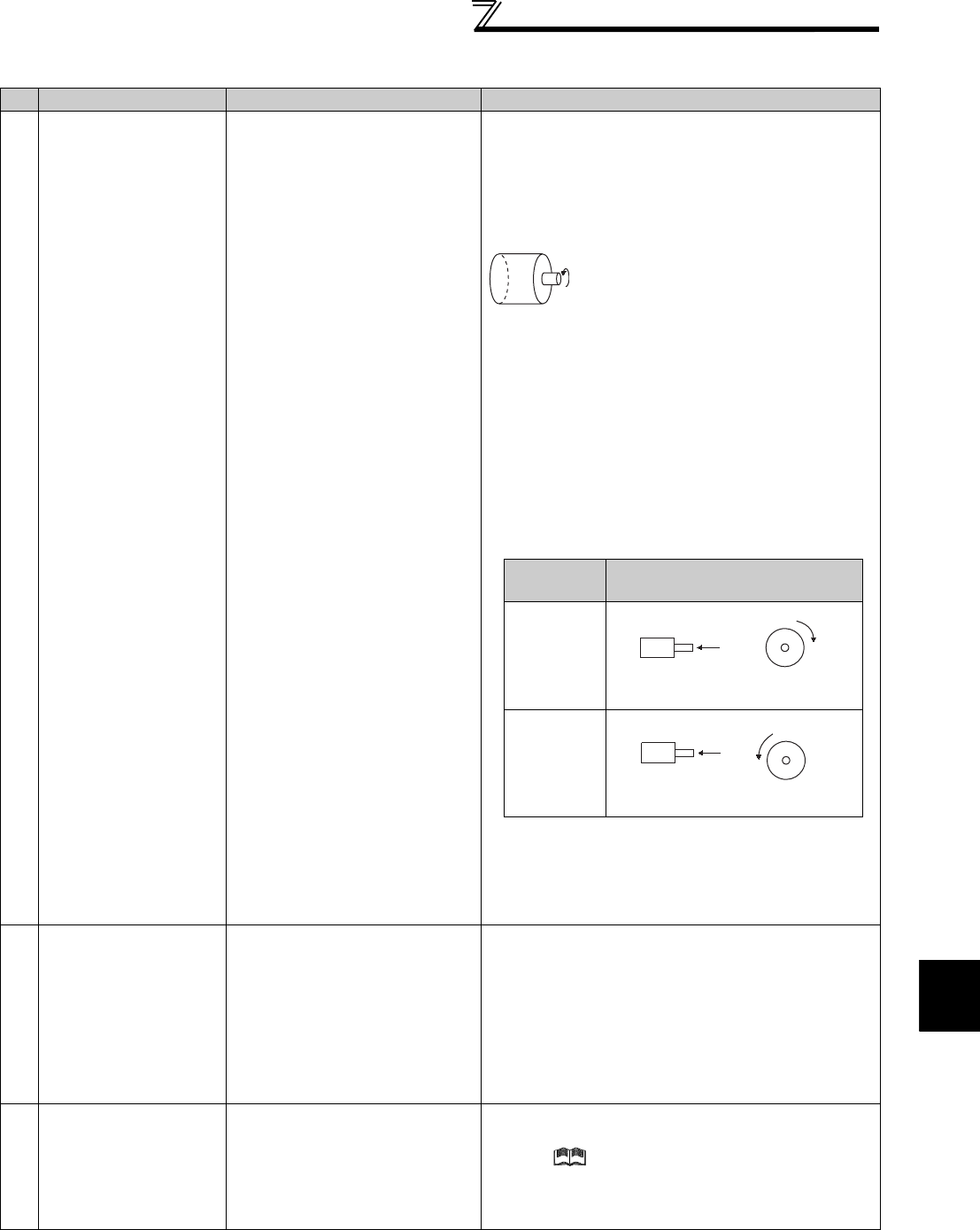

Pr. 359

Setting

Relationship between the Motor

and Encoder

0

1

(Initial value)

A

Encoder

CW

Clockwise direction as viewed

from A is forward rotation

CCW

A

Encoder

Counter clockwise direction as

viewed from A is forward rotation