139

PID control (Pr. 128 to Pr. 134)

PARAMETERS

3

3.14.2 E

2

PROM write selection (Pr. 342)

You can select either E

2

PROM or RAM to which parameters to be written during computer link communication

operation (RS-485 communication by PU connector) and operation with a communication option. When changing

the parameter values frequently, write them to the RAM (Pr. 342 = 1).

3.15 PID control (Pr. 128 to Pr. 134)

3.15.1 PID control (Pr. 128 to Pr. 134 )

<Setting>

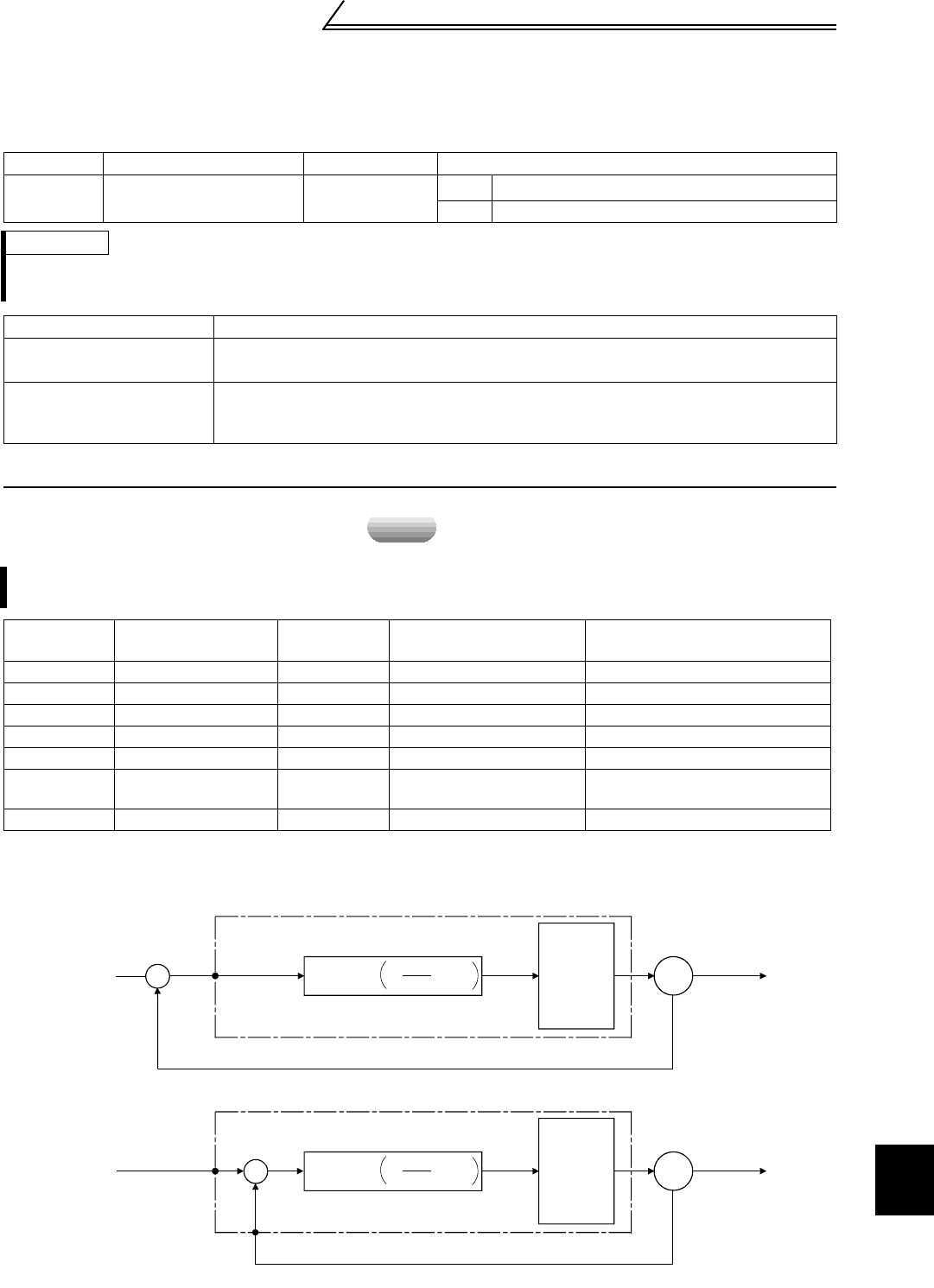

(1) Basic PID control configuration

Parameter Name Factory Setting Setting Value

342

E

2

PROM write selection

0

0

Write into E

2

PROM

1 Write into RAM

REMARKS

When the parameter setting is " not written to E

2

PROM" (setting = 1), the settings return to the original values (values saved in

the E

2

PROM) at power on reset or terminal reset.

Pr. 342 Setting

0

(factory setting)

E

2

PROM write

Powering off the inverter will not erase the changed parameter values.

1

RAM write

Powering off the inverter will erase the changed parameter values. Therefore, the parameter

values available when power is switched on again are the values stored in E

2

PROM last time.

The inverter can be used to exercise process control, e.g. flow rate, air volume or pressure.

z The voltage input signal (0 to ±10V) is used as a feedback value to constitute a feedback system for PID control.

Parameter

Number

Name

Factory

Setting

Setting Range Remarks

128 PID action selection 10 10, 11, 30, 31

129 PID proportional band 100% 0.1 to 1000%, 9999 9999: No proportional control

130 PID integral time 1s 0.1 to 3600s, 9999 9999: No integral control

131 Upper limit 9999 0 to 100%, 9999 9999: Function invalid

132 Lower limit 9999 0 to 100%, 9999 9999: Function invalid

133

PID action set point for

PU operation

0% 0 to 100%

134 PID differential time 9999 0.01 to 10.00s, 9999 9999: No differential control

speed

Kp

PID

operation

1 +

Ti·S

1

+ Td·S

x

Deviation

Process

value

fi

Manipulated

variable

Drive

circuit

Motor

IM

Kp: Proportional constant Ti: Integral time S: Operator Td: Differential time

Set

point

Inverter

Terminal 1

Pr.128 = 10, 11

x

Deviation

Process value

fi

Manipulated

variable

IM

Set

point

Terminal 2

Pr.128 = 30, 31

+

-

Drive

circuit

Motor

Inverter

Kp

PID

operation

1 +

Ti·S

1

+ Td·S

Terminal 1