3-48 FUEL SYSTEM (DFI)

Fuel Injectors (Service Code/Character-41, 42, 43, 44/InJ1, InJ2, InJ3, InJ4)

•

Replace the seals [A] with new ones.

•

Apply grease to the inside and outside of seals.

•

Install:

Delivery Pipe Assembly

Collars

•

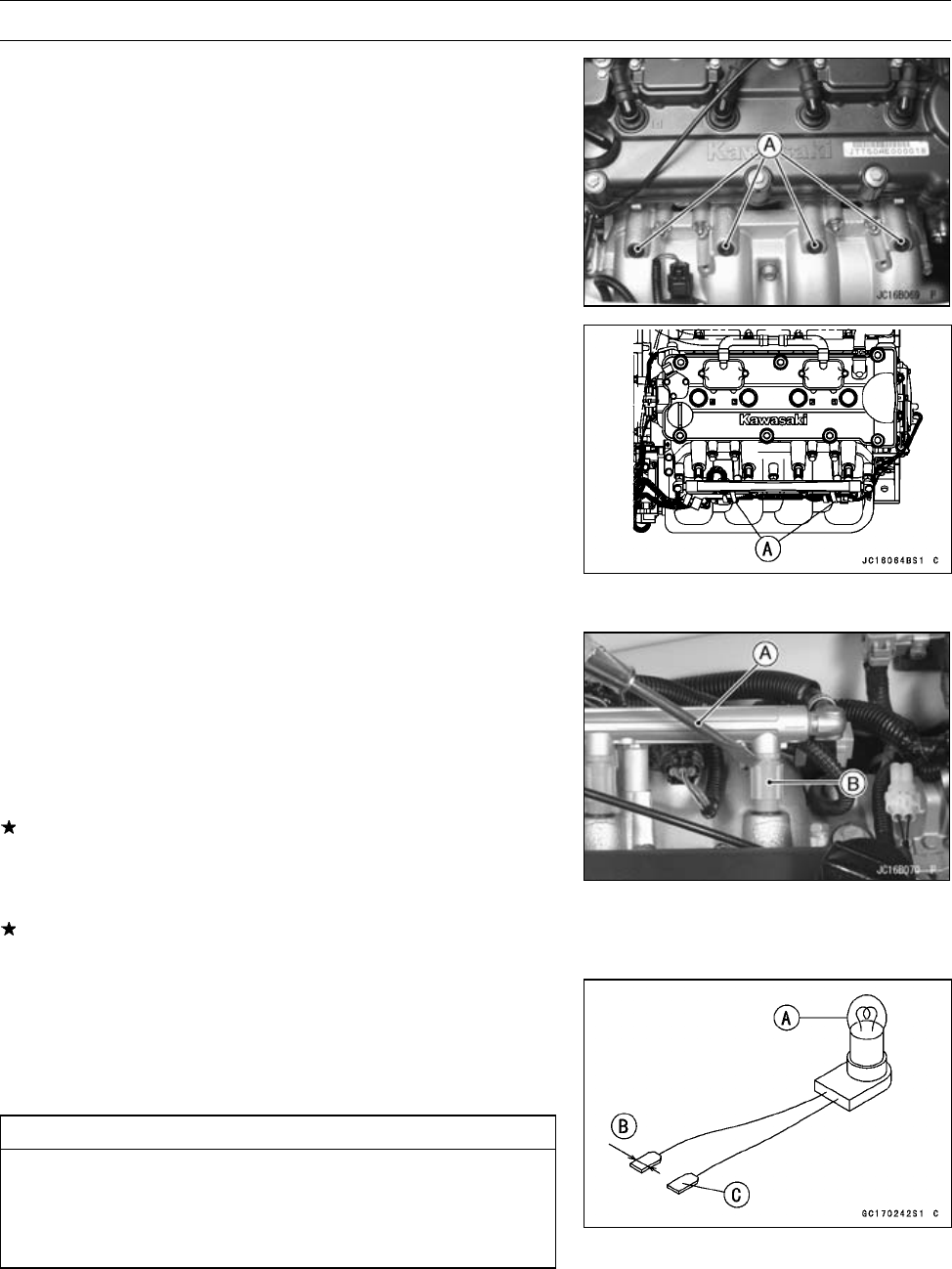

Install the clamps [A] as shown.

•

Tighten:

Torque - Delivery Pipe Mounting Bolts: 7.8 N·m (0.80 kgf·m,

69 in·lb)

•

Install the fuel hoses (see Cable, Wire, and Hose Routing

section in Appendix chapter).

○

For JT1500-A2 model ∼; Replace the double spring

clamps with new ones. (see Fuel System Diagram)

Audible Inspection

•

Start the engine.

•

Apply the tip of a screwdriver [A] to the injector [B]. Put

the grip end onto your ear, and listen whether the injector

is clicking or not.

•

A sound scope can also be used.

•

Do the same for the other injector.

If all the injectors click at a regular intervals, the injectors

are good.

○

The click interval becomes shorter as the engine speed

rises.

If either injector doesn’t click, perform the “Injector Signal

Test” for injector operation.

Injector Signal Test

•

Prepare four test lights set with male terminals as shown.

Rating of Bulb [A]: 12 V, 3 ∼ 3.4 W

Terminal Width [B]: 1.8 mm (0.07 in.)

Terminal Thickness [C]: 0.8 mm (0.03 in.)

CAUTION

Do not use larger terminals than specified above. A

larger terminal could damage the injector main har-

ness connector (female), leading to harness repair

or replacement.