3-20 FUEL SYSTEM (DFI)

DFI Servicing Precautions

For JT1500-A2 ∼;

○

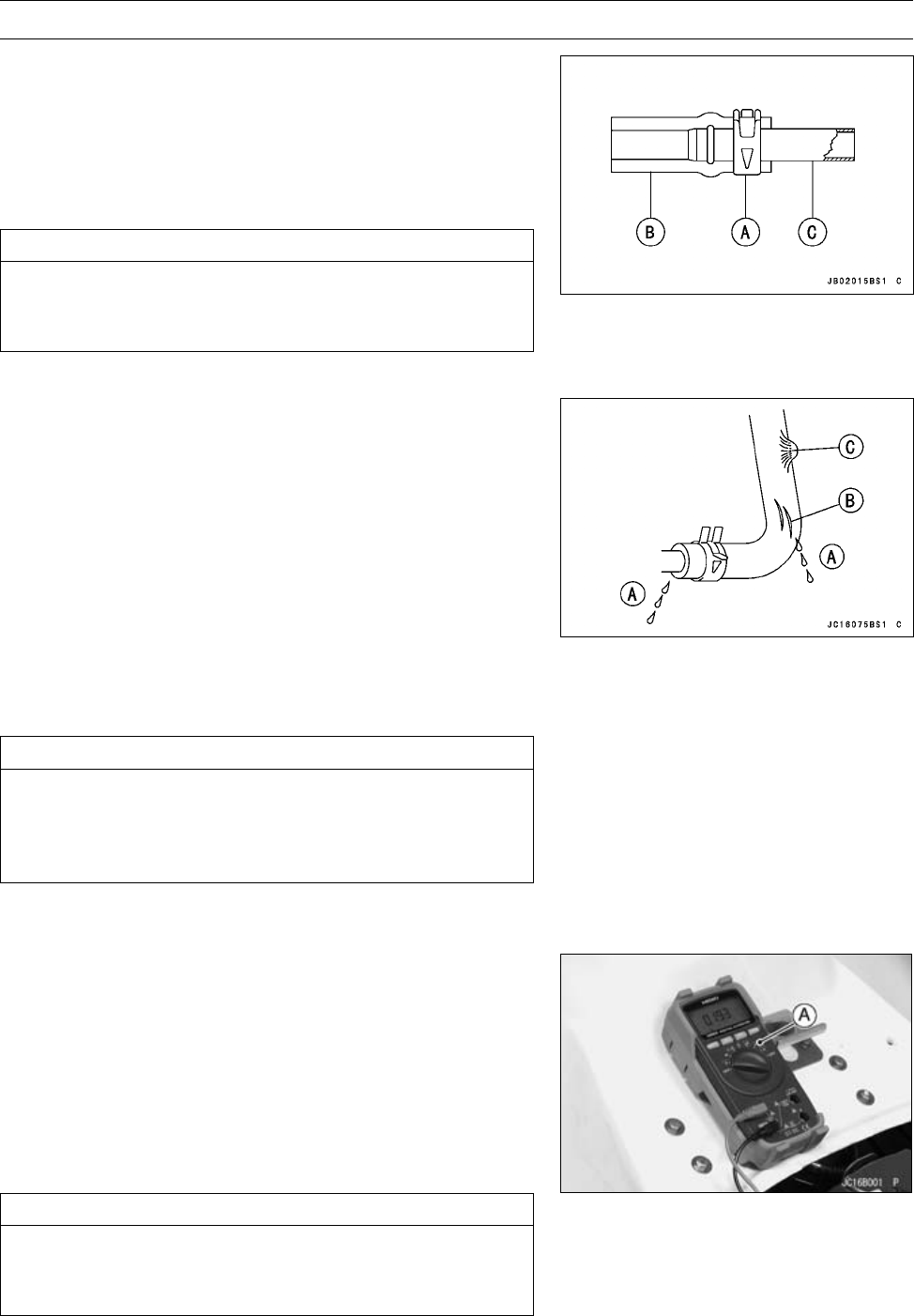

Install the double spring clamp in the position as shown,

and securely pull up the clamp stopper with pliers. Check

the fuel system for l eaks after hose installation.

Fuel Hose [B]

Double Spring Clamp [A]

Fuel Pipe [C]

CAUTION

Do not reuse the double spring clamps on the fuel

line. Reusing will cause fuel leakage.

Replace the double spring clamps with new ones.

○

Replace the fuel hose if it has been sharply bent or kinked.

○

The high pressure inside the fuel line can cause fuel to

leak [A] or the hose to burst. Bend and twist the fuel hose

while examining it.

○

Replace the hose if any cracks [B] or bulges [C] are no-

ticed.

○

When checking the DFI parts, do not run the engine for

15 seconds or more without auxiliary cooling (see General

Information chapter).

CAUTION

If running the engine without the auxiliary cooling

for 15 seconds or more (even at idle speed), the rub-

ber component relative to the Exhaust System may

be damaged.

○

Execute the auxiliary cooling securely in case that fre-

quent engine running is required.

•

When checking the DFI parts, use a digital meter w hich

can be read two decimal place voltage or resistance.

○

The DFI part connectors have seals, including the ECU.

When measuring the input or output voltage with the

connector joined, use the needle adapter set. Insert the

needle adapter inside the seal until the needle adapter

reaches the terminal.

Digital Meter [A]

Special Tool - Needle Adapter Set: 57001-1457

CAUTION

Insert the needle adapter straight along the terminal

in the connector to prevent short-circuit between

terminals.