ENGINE TOP END 6-33

Cylinder, Pistons

•

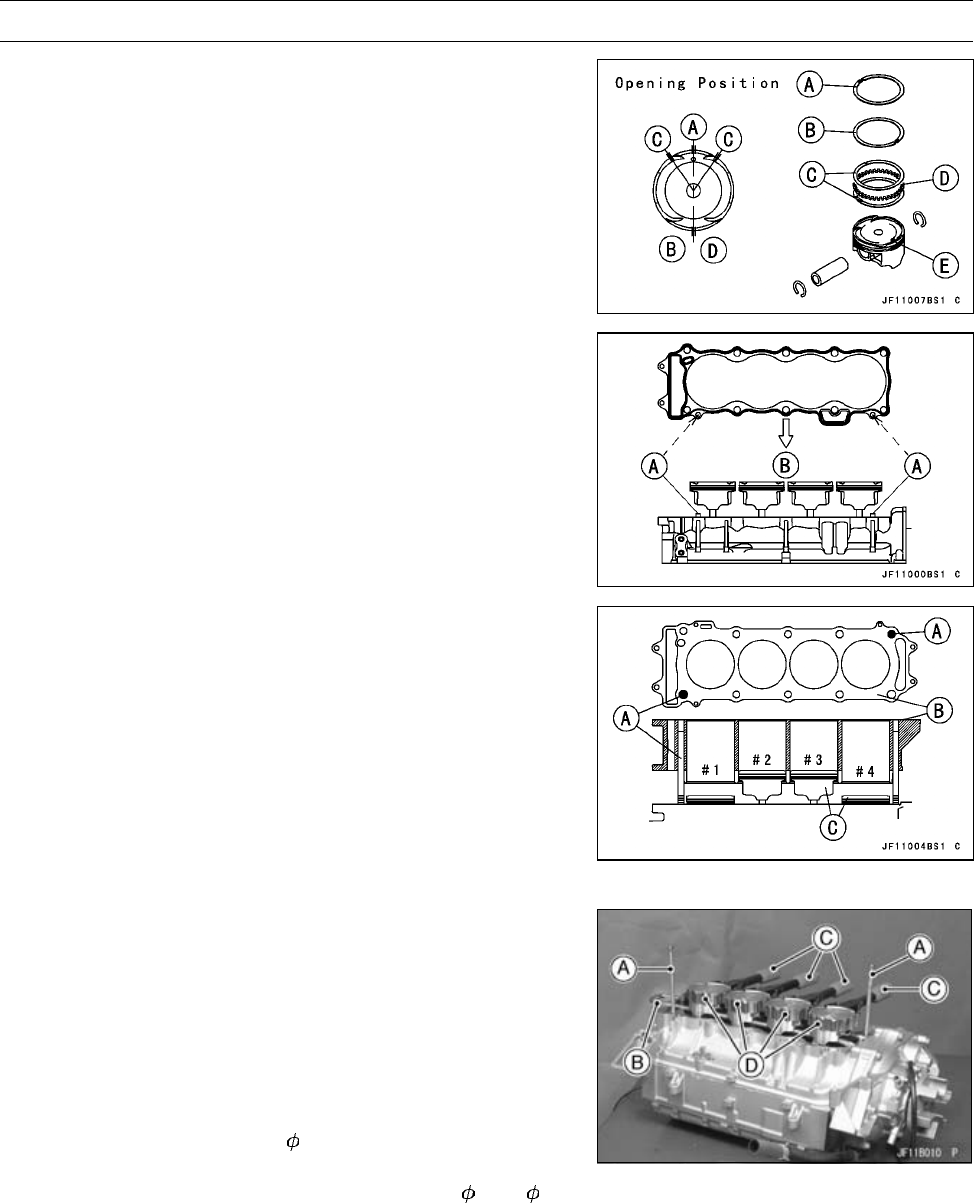

The piston ring openings must be positioned as shown in

the figure. The openings of the oil ring steel rails must be

about 30 ∼ 40° of angle from the opening of the top ring.

[A] Top Ring

[B] Second Ring

[C] Oil Ring Steel Rails

[D] Oil Ring Expander

[E] Hollow (Exhaust Side)

•

Replace the cylinder gasket with a new one, and install

the pins [A] and new cylinder gasket.

Exhaust Side [B]

•

Apply molybdenum disulfide oil solution to the cylinder

bore, external of pistons and piston rings.

•

Insert the piston in the cylinder by two methods.

With the Hand

•

Position the crankshaft at #2, #3 piston TDC.

•

Install the two cylinder head bolts [A] diagonally in the

crankcase.

•

Install the cylinder block [B].

Pistons [C]

○

First insert the #2, #3 pistons, and then rotate the crank-

shaft at 90° angle.

○

Insert the piston rings with your thumbs or the thin (–)

screw driver.

With the Special Tools

•

Install the two cylinder head bolts [A] diagonally in the

crankcase.

•

Slip the piston bases [B] under the pistons to hold them

level.

•

Compress the piston rings using the piston ring compres-

sor grips [C] and piston ring compressor belts [D] with

chamfered side upward.

Special Tools - Piston Base, 8: 57001-1604

Piston Ring Compressor Grip: 57001-1095

Piston Ring Compressor Belt,

80 ∼ 91:

57001-1320

•

Push down vigorously the cylinder aligning the cylinder

bores with all the piston heads.

•

Install the cylinder so that its angle aligns the piston angle

after removing the piston ring compressor belts.

•

Install the removed parts.