3-86 FUEL SYSTEM (DFI)

Fuel Pump

•

Remove the front storage pocket (see Hull/Engine Hood

chapter).

•

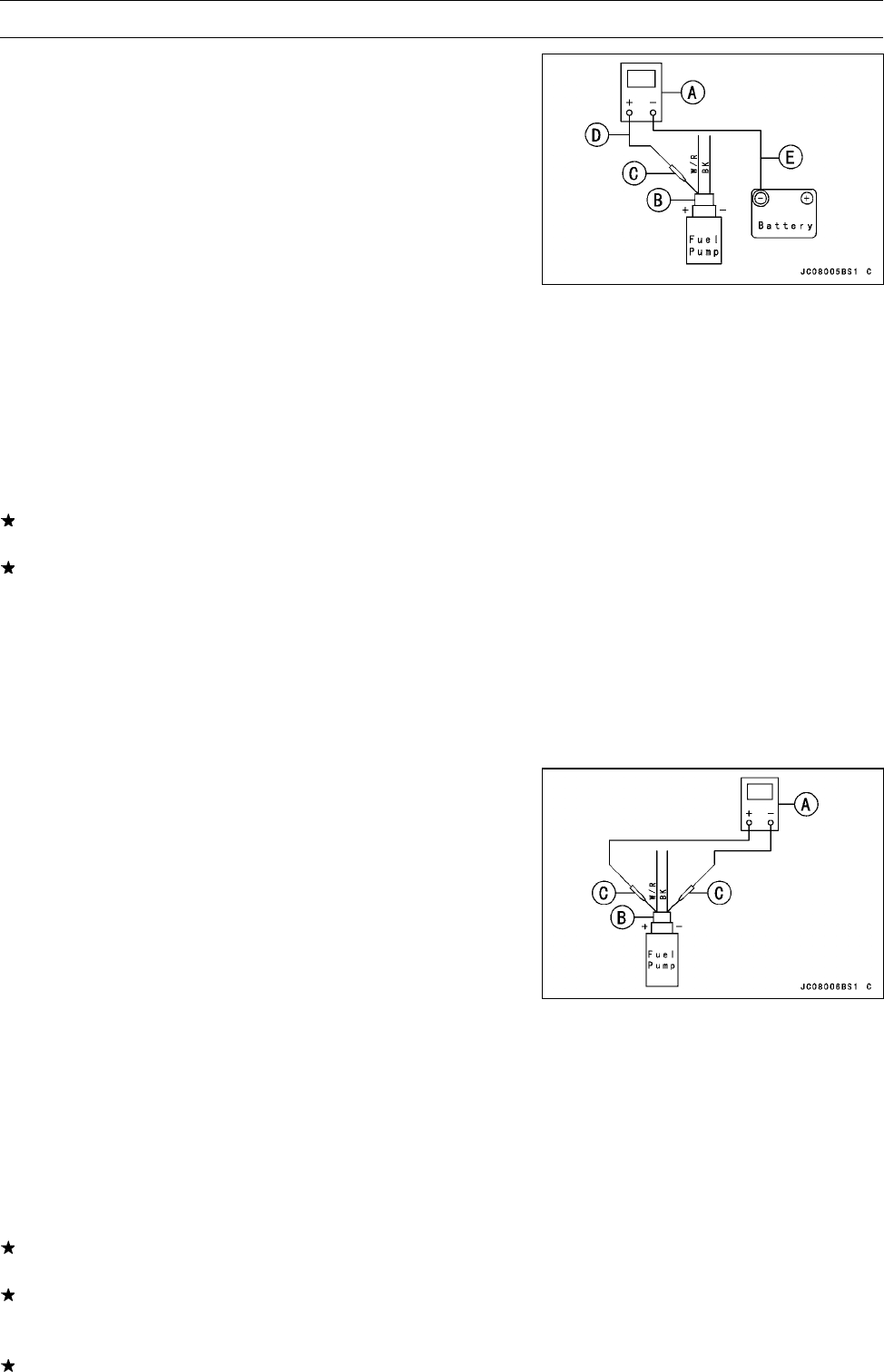

Connect the hand tester (25 V DC) [A] to the fuel pump

lead connector [B], using the needle adapter set [C].

Special Tools - H and Tester: 57001-1394

Needle Adapter Set: 57001-1457

•

Turn the ignition switch ON and push the lanyard key un-

der the stop button.

•

Pushing the start button, run the engine 5 ∼ 6 seconds at

idling to measure the power source voltage.

○

Wait 15 seconds before using the starter again.

Pump Power Source Voltage

Connections

Tester (+) → W/R lead [D]

Tester (–) → Battery (–) Terminal [E]

Power Source Voltage at Pump Lead Connector

Standard:

Battery Voltage

If the reading is good, the power source voltage is normal.

Inspect the operating voltage.

If there is no battery voltage, check the following:

MainFuse20A

Wiring for Fuel Pump Power Source (see Fuel Pump

Circuit in this chapter)

Operating Voltage Inspection

NOTE

○

Be sure the battery is fully charged.

•

Remove the front storage pocket (see Hull/Engine Hood

chapter).

•

Connect the hand tester [A] to the connector [B], using

the needle adapter set [C].

Special Tools - H and Tester: 57001-1394

Needle Adapter Set: 57001-1457

•

Turn the ignition switch ON and push the lanyard key un-

der the stop button.

•

Pushing the start button, run the engine 5 ∼ 6 seconds at

idling to measure the operating voltage.

○

Wait 15 seconds before using the starter again.

Pump Operating Voltage

Connections

Tester (+) → W/R lead

Tester (–) → BK lead

Operating Voltage

Standard:

Battery Voltage

If the reading stays on battery voltage but the pump

doesn’t work, replace the pump.

If there is no battery voltage at all, check the ECU for

its ground and power supply (see ECU Power Supply In-

spection).

If the ground and power supply are good, check the fuel

pump wiring.