2-28 PERIODIC MAINTENANCE

Periodic Maintenance Procedures

•

Make sure the above hoses are routed properly and se-

cured with the clamps away from any moving parts and

sharp edged portions.

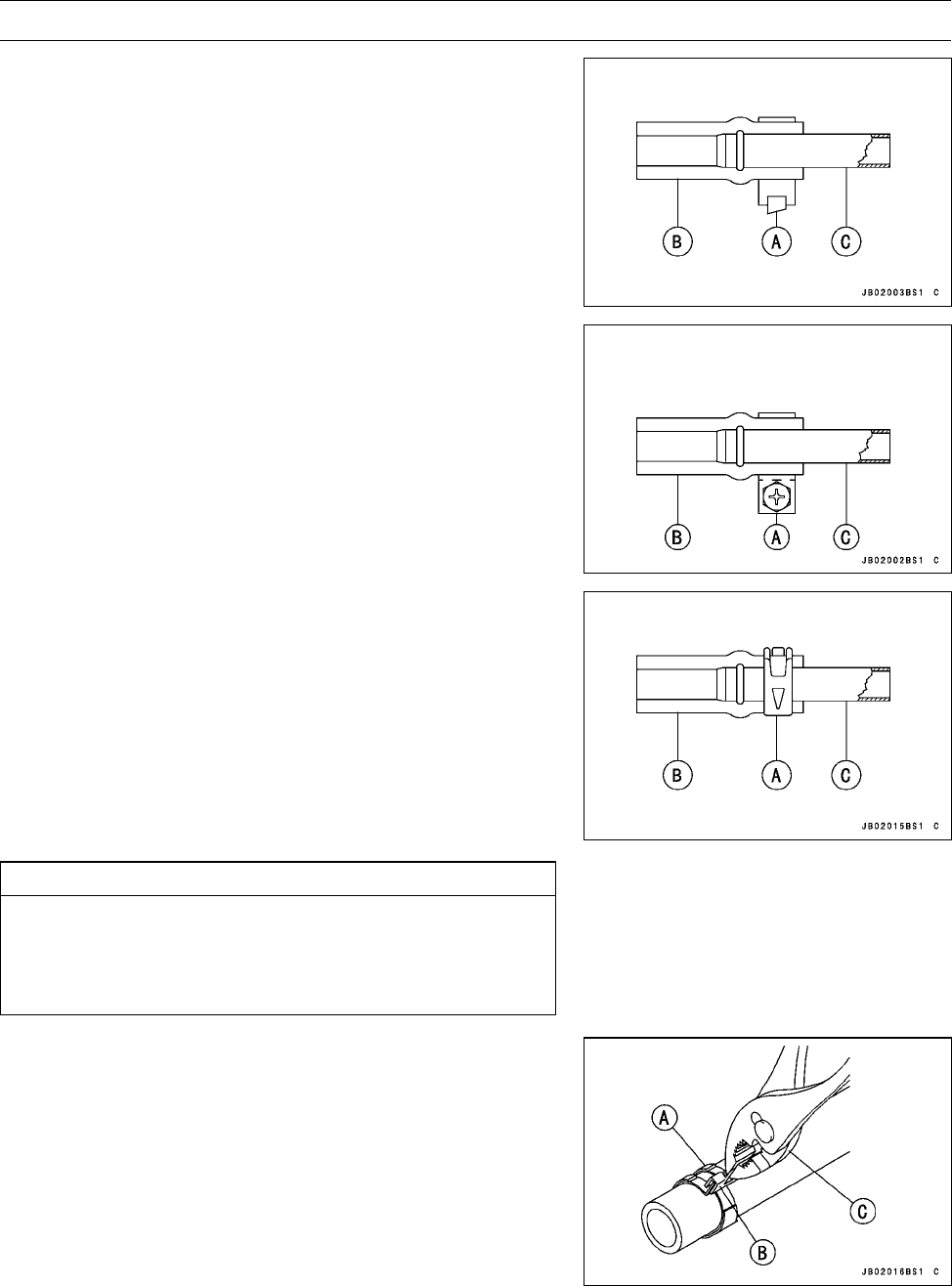

Plastic Clamp [A]

Hose [B]

Hose Fitting [C]

NOTE

○

The majority of bilge hoses have no clamps at the hose

ends.

Metal Clamp [A]

Hose [B]

Hose Fitting [C]

NOTE

○

Check the fuel and exhaust tubes for signs of wear, de-

terioration, damage or leakage. Replace if necessary.

○

Make sure the above tubes are secured with the metal

gear clamps away from any parts.

JT1500-A2 ∼;

Double Spring Clamp [A]

Hose [B]

Hose Fitting [C]

NOTE

○

Check the fuel hoses for signs of wear, deterioration,

damage or leakage. Replace if necessary.

○

Make sure the above hoses are secured with the double

spring clamps away from any parts.

CAUTION

Do not reuse the double spring clamps on the fuel

line.

Reusing will cause fuel leakage.

Replace the double spring clamps with new ones.

•

Replacement procedure for the double spring clamp is as

follows.

○

Remove the double spring clamp with pliers and discon-

nect the fuel hose.

○

Install the fuel hose and insert the new double spring

clamp [A] with the clamp stopper [B].

○

Pull up the clamp stopper with pliers [C].

NOTE

○

Position the double spring clamp on the fuel hose cor-

rectly.