ENGINE TOP END 6-23

Cylinder Head

•

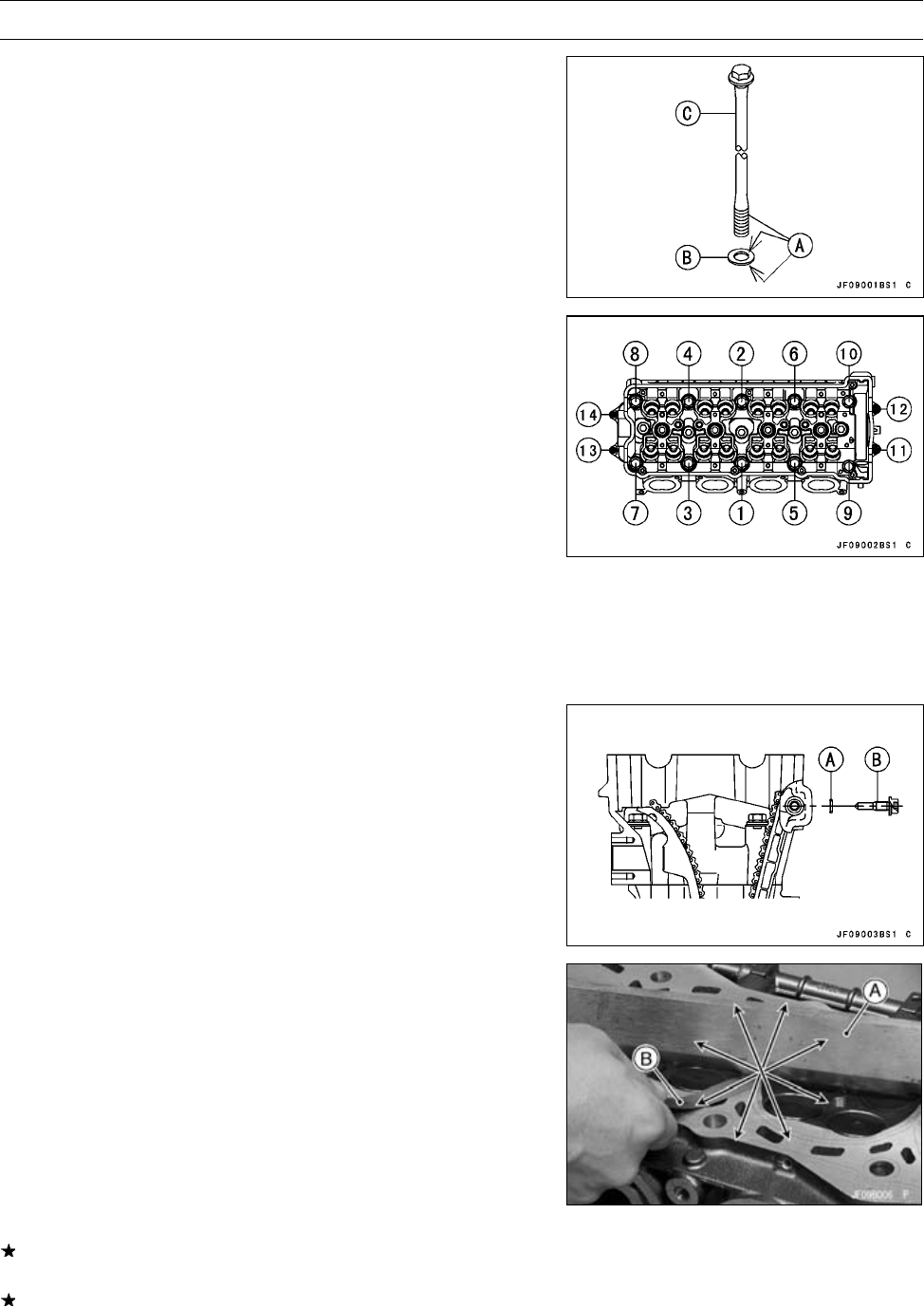

Apply molybdenum disulfide oil solution [A] to both sides

of the M11 cylinder head bolt washers [B] and the thread

of head bolts [C].

•

Install the cylinder head.

•

First, tighten the M11 cylinder head bolts following the

tightening sequence [1 ∼ 10].

Torque - Cylinder Head Bolts (M11):

First:23N·m(2.3kgf·m,17ft·lb)

Final: 59 N·m (6.0 kgf·m, 44 ft·lb)

•

Next, tighten the M7 cylinder head bolts following the

tightening sequence [11 ∼ 12].

Torque - Cylinder Head Bolts (M7): 20 N·m (2.0 kgf·m, 14

ft·lb)

•

Lastly, tighten the M6 cylinder head bolts following the

tightening sequence [13 ∼ 14].

Torque - Cylinder Head Bolts (M6): 12 N·m (1.2 kgf·m, 104

in·lb)

•

Apply grease to the O-ring [A].

•

Install:

O-ring

Upper Exhaust Side Camshaft Chain Guide Bolt [B]

•

Tighten:

Torque - Exhaust Side Camshaft Chain Guide Bolt (Upper):

25 N·m (2.5 kgf·m, 18 ft·lb)

•

Install the camshafts (see Camshaft Installation).

Cylinder Head Warp

•

Remove the cylinder head (see Cylinder Head Removal).

•

Clean the cylinder head.

•

Lay a straightedge across the lower surfaceof the cylinder

head at several positions.

•

Measure the space between the straightedge [A] and the

head with a thickness gauge [B].

Cylinder Head Warp

Standard:

–––

Service Limit: 0.05 mm (0.002 in.)

If the cylinder head is warped more than the service limit,

replace it.

If the cylinder head is warped less than the service limit,

repair the head by rubbing the lower surface on emery

paper secured to a surface plate (first No. 200, then No.

400).