6-24 ENGINE TOP END

Valves

Valve Clearance Check

•

Refer to Valve Clearance Inspection and Adjustment in

the Periodic Maintenance chapter.

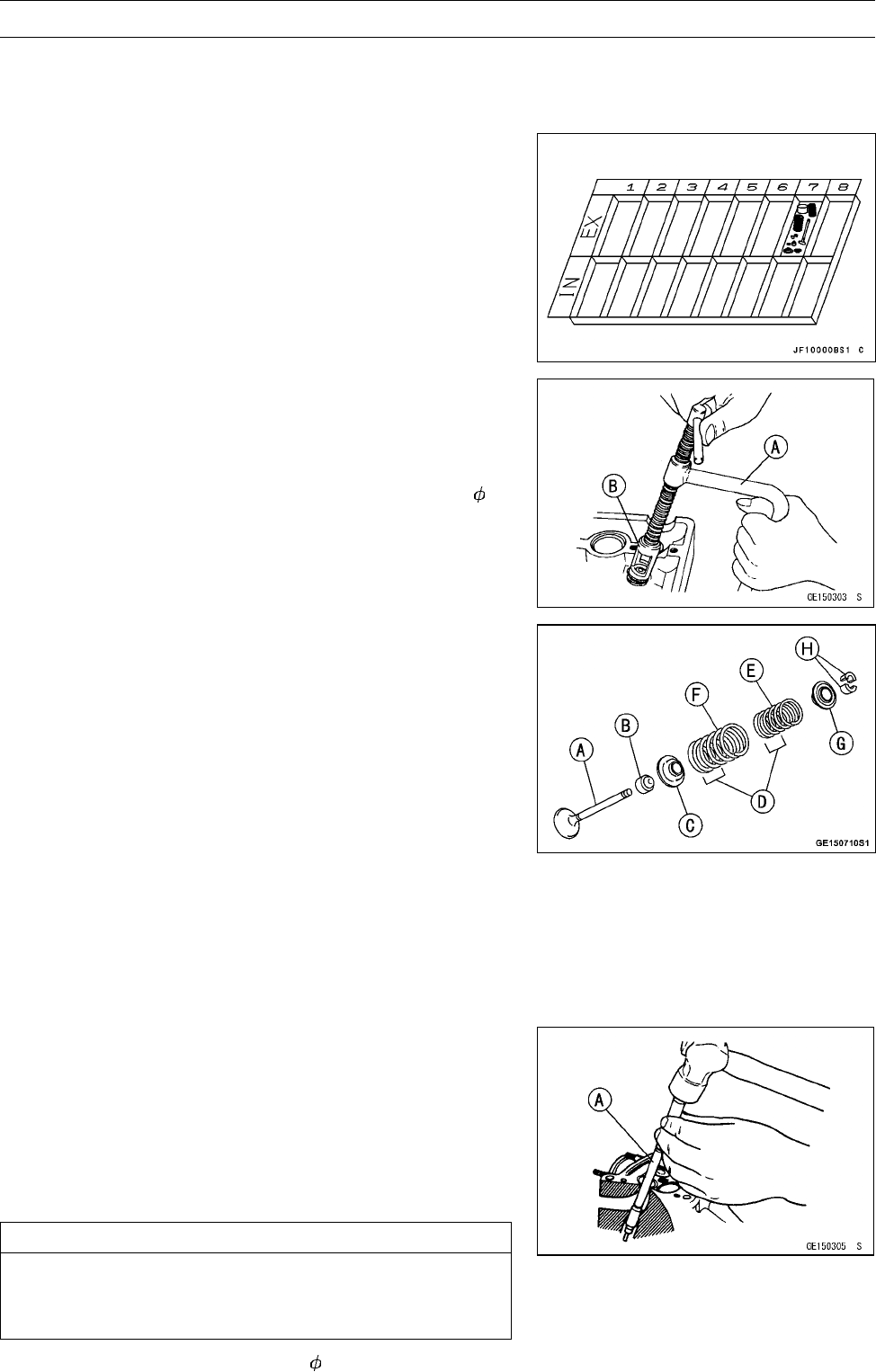

Valve Removal

•

Remove the cylinder head (see Cylinder Head Removal).

•

Remove the valve lifter and shim.

○

Mark and record the valve lifter and shim locations so they

can be installed in their original positions.

•

Using the valve spring compressor assembly, remove the

valve.

Special Tools - Valve Spring Compressor Assembly: 57001

-241 [A]

Valve Spring Compressor Adapter,

22:

57001-1202 [B]

Valve Installation

•

Replace the oil seal with a new one.

•

Apply thin coat of molybdenum disulfide grease to the

valve stem before valve installation.

•

Install the springs so that the closed coil end faces down-

wards.

Valve Spring Paint Color:

EX-Red

IN-Blue

[A] Valve Stem

[B] Oil Seal

[C] Spring Seat

[D] Closed Coil End

[E] Valve Springs (Inner)

[F] Valve Springs (Outer)

[G] Retainer

[H] Split Keepers

Valve Guide Removal

•

Remove:

Valve(seeValveRemoval)

Oil Seal

Spring Seat

•

Heat the area around the valve guide to 120 ∼ 150°C (248

∼ 302°F), and hammer lightly on the valve guide arbor [A]

to remove the guide from the top of the head.

CAUTION

Do not heat the cylinder head with a torch. This will

warp the cylinder head. Soak the cylinder head in

oil and heat the oil.

Special Tool - Valve Guide Arbor, 5: 57001-1203