6-28 ENGINE TOP END

Valves

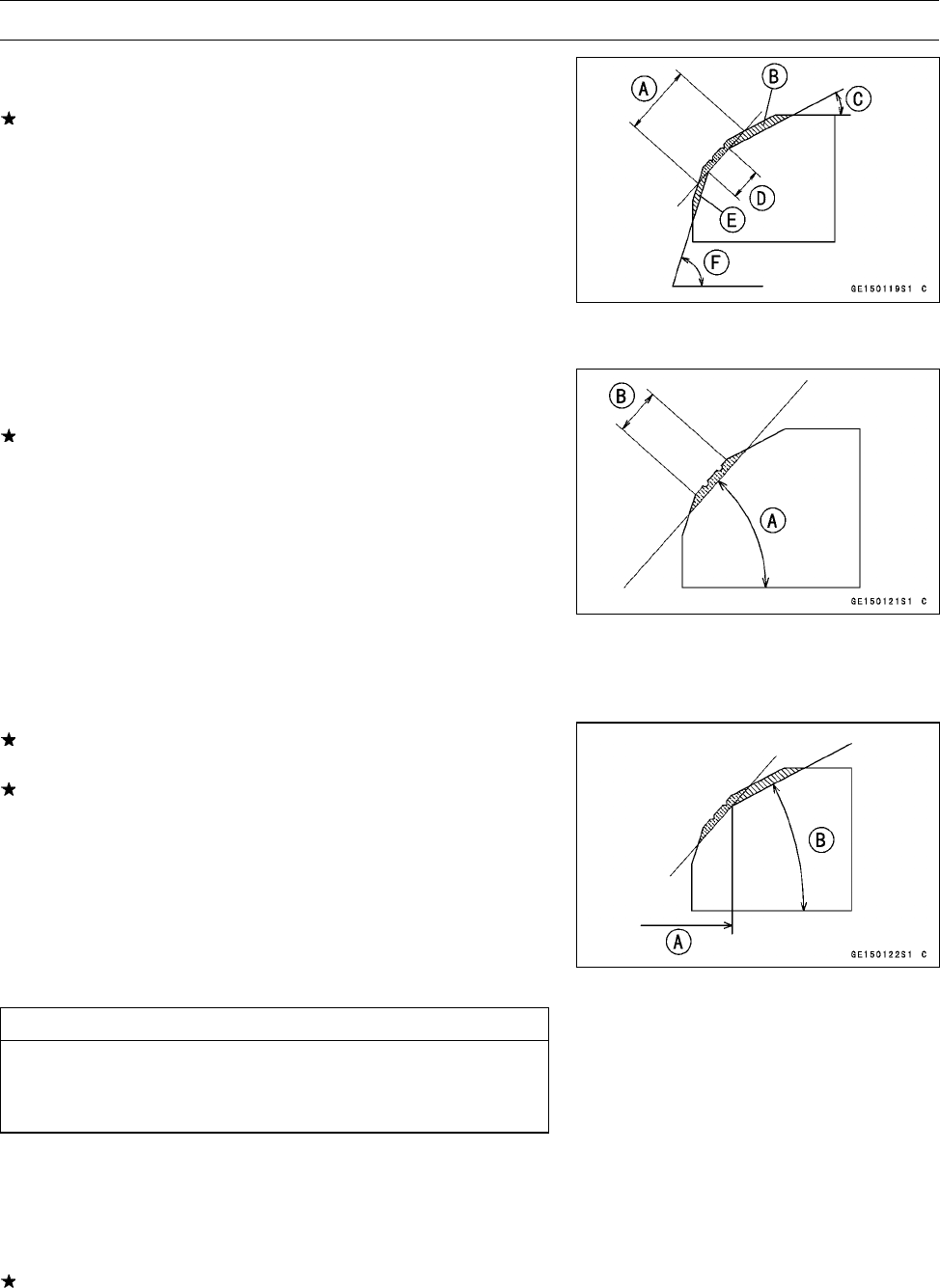

•

Measure the outside diameter of the seating surface with

a vernier caliper.

If the outside diameter of the seating surface is too small,

repeat the 45° grind until the diameter is within the spec-

ified range.

Widened Width [A] of engagement by machining with

45° cutter

Ground Volume [B] by 32° cutter

32° [C]

Correct Width [D]

Ground Volume [E] by 60° or 55° cutter

60° or 55° [F]

•

Measure the outside diameter of the seating surface with

a vernier caliper.

If the outside diameter of the seating surface is too small,

repeat the 45° grind [A] until the diameter is within the

specified range.

Original Seating Surface [B]

NOTE

○

Remove all pittings of flaws from 45° ground surface.

○

After grinding with 45° cutter, apply thin coat of machin-

ist’s dye to seating surface. This m akes seating surface

distinct and 32° and 60° grinding operation easier.

○

When the valve guide is replaced, be sure to grind with

45° cutter for centering and good contact.

If the outside diameter [A] of the seating surface is too

large, make the 32° grind described below.

If the outside diameter of the seating surface is within the

specified range, measure the seat width as described be-

low.

•

Grind the seat at a 32° angle [B] until the seat O.D. is

within the specified range.

○

To make the 32° grind, fit a 32° cutter into the holder, and

slide it into the valve guide.

○

Turn the holder one turn at a time while pressing down

very lightly. Check the seat after each turn.

CAUTION

The 32° cutter removes material very quickly.

Check the seat outside diameter frequently to pre-

vent overgrinding.

○

After making the 32° grind, return to the seat O.D. mea-

surement step above.

•

To measure the seat width, use a vernier caliper to mea-

sure the width of the 45° angle portion of the seat at sev-

eral places around the seat.

If the seat width is too narrow, repeat the 45° grind until

the seat is slightly too wide, and then return to the seat

O.D. measurement step above.