3-78 FUEL SYSTEM (DFI)

Fuel Line

Fuel Pressure Inspection

NOTE

○

Be sure the battery is fully charged.

•

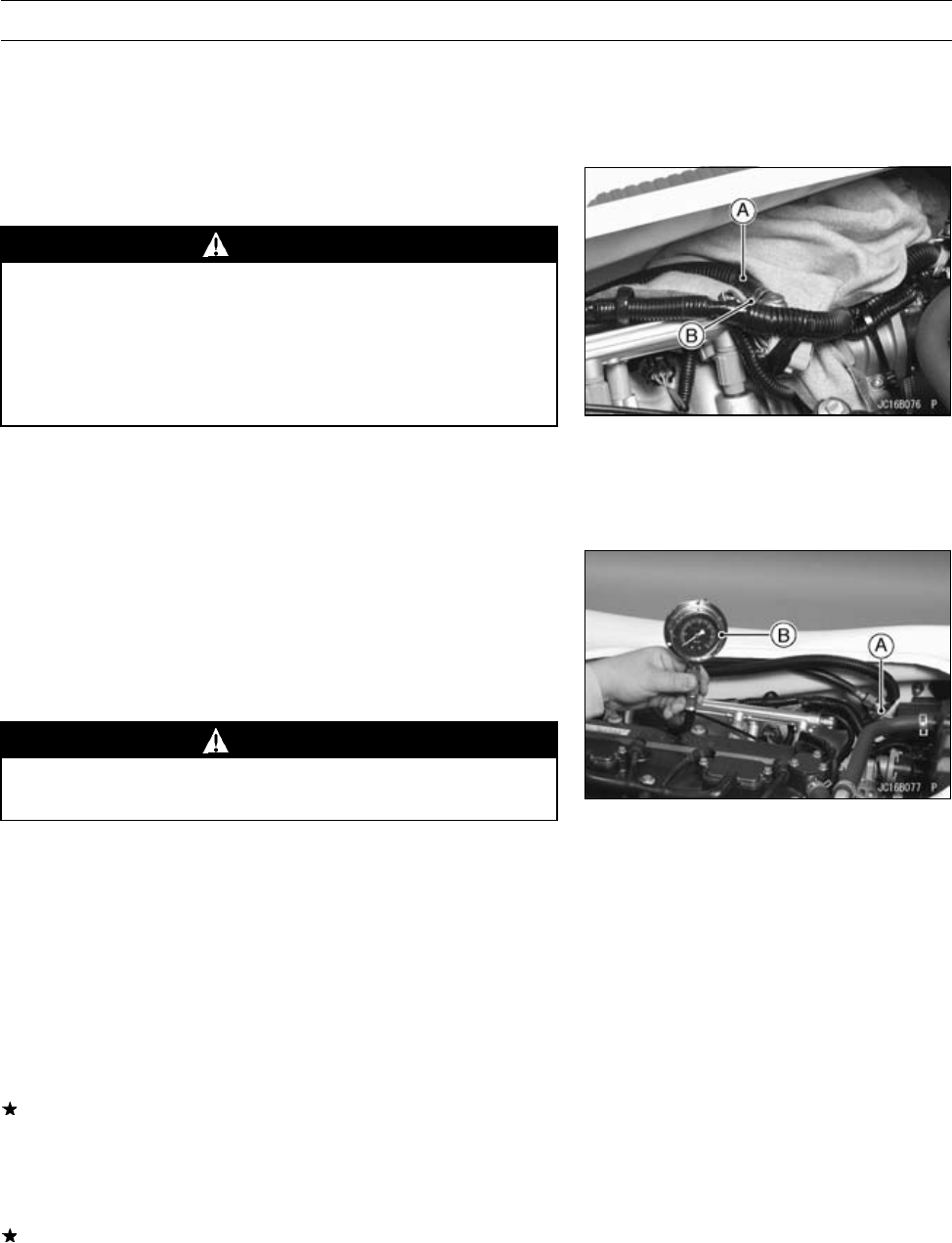

Be sure to place a piece of cloth under the fuel supply

hose [A] of the fuel delivery pipe.

WARNING

Be prepared for fuel spillage; any spilled fuel must

be completely wiped up immediately.

When the fuel hose is disconnected, fuel spills out

from the hose and the pipe because of residual

pressure. Cover the hose connection with a piece

of clean cloth to prevent fuel spillage.

•

Loosen the clamp bolt [B] and pull out the fuel supply

hose.

•

For JT1500-A2 model ∼; Loosen the double spring clamp

[B] with pliers and pull out the fuel supply hose.

•

Quickly install the fuel pressure gauge adapter [A] be-

tween the fuel supply pipe and the fuel supply hose.

•

Connect the pressure gauge [B] to the fuel pressure

gauge adapter.

Special Tools - Fuel Pressure Gauge Adapter: 57001-1463

Oil Pressure Gauge, 5 kgf/cm²: 57001-125

WARNING

Do not try to start the engine with the fuel hoses

disconnected.

•

Start the engine, and let it idle.

•

Measure the fuel pressure with the engine idling.

Fuel Pressure (idling)

Standard: approx. 294 kPa (3.0 kgf/cm², 43 psi)

NOTE

○

The gauge needle will fluctuate. Read the pressure at

the average of the maximum and minimum indications.

If the fuel pressure is much higher than the specified,

check the following:

Fuel Hose from Gauge Adapter to Fuel Pump Return

Pipe for Sharp Bend, Kinking, or Clogging

Fuel Pump

If the fuel pressure is much lower than specified, check

the following:

Fuel Line Leakage

Fuel Injectors

Fuel Pump

Amount of Fuel Flow (see Fuel Flow Rate Inspection)