2-22 PERIODIC MAINTENANCE

Periodic Maintenance Procedures

Pump and Impeller

Impeller Inspection

•

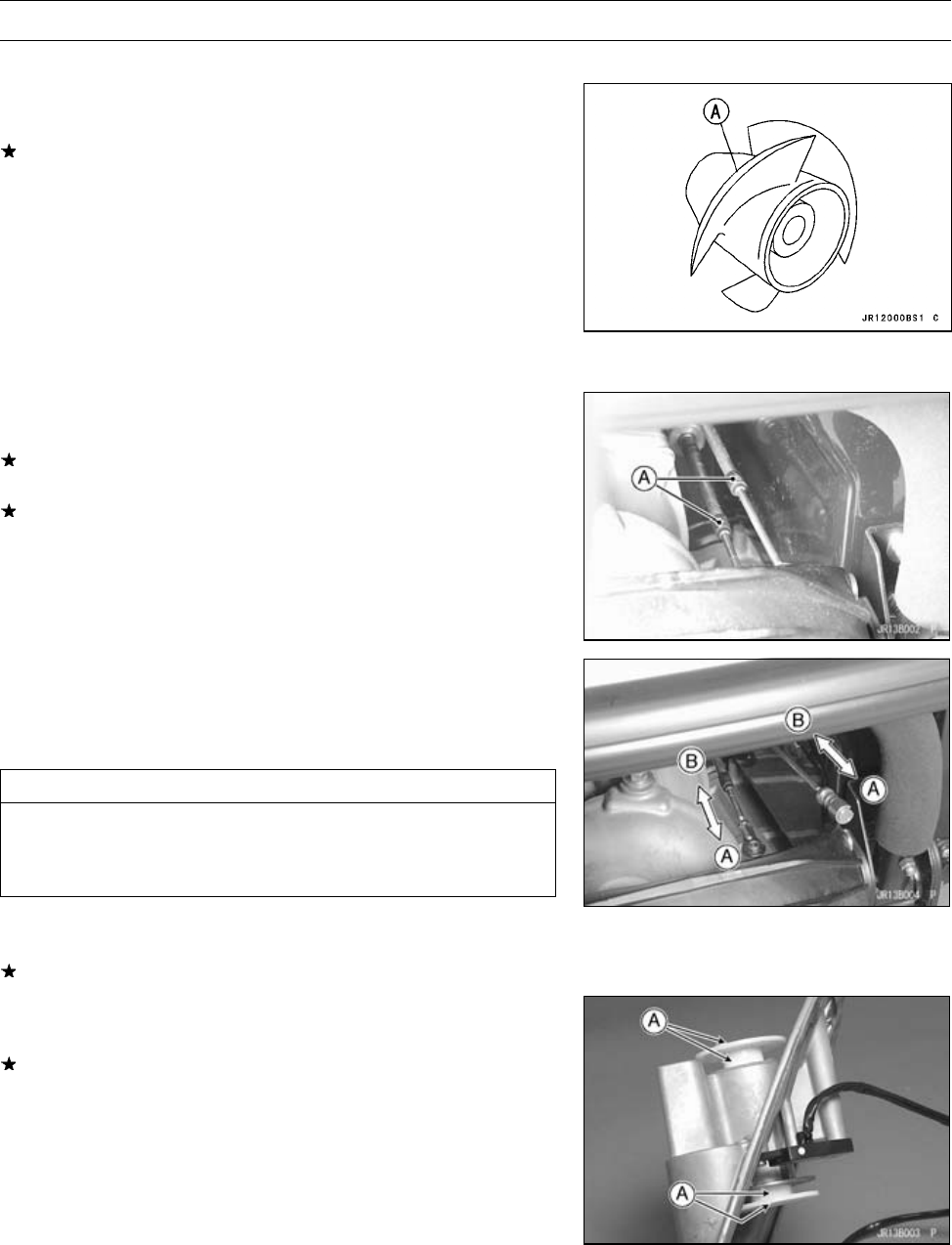

Examine the impeller. [A]

If there is pitting, deep scratches, nicks or other damage,

replace the impeller.

NOTE

○

Minor nicks and gouges in the impeller blades can be

removed with abrasive paper or careful filing. Smooth

leading edges are especially important to avoid cavita-

tion.

Steering

Steering Cable/Shift Cable Inspection

•

Examine the steering cable or shift cable.

If each cables or cable housings are kinked or frayed,

replace the cables.

If the each seal [A] at either end of each cable is damaged

in any way, replace the cables.

•

Be certain that each c able moves freely in both directions.

•

Disconnect the cable joints at each end of each cable.

○

Take out the cable joint bolt or ball joint and disconnect

the cable j oint.

CAUTION

Never lay the watercraft on the right side. Water in

the exhaust system may drain back into the engine

causing serious damage.

○

Slide the inner cable back [A] and forth [B] in each cable

housings.

If each cable does not move freely, replace it.

Handlebar Pivot Lubrica tion

•

Check the bushings for damage and wear.

If the bushings are damaged or worn, replace them.

•

Grease:

Bushings [A]