2-16 PERIODIC MAINTENANCE

Periodic Maintenance Procedures

•

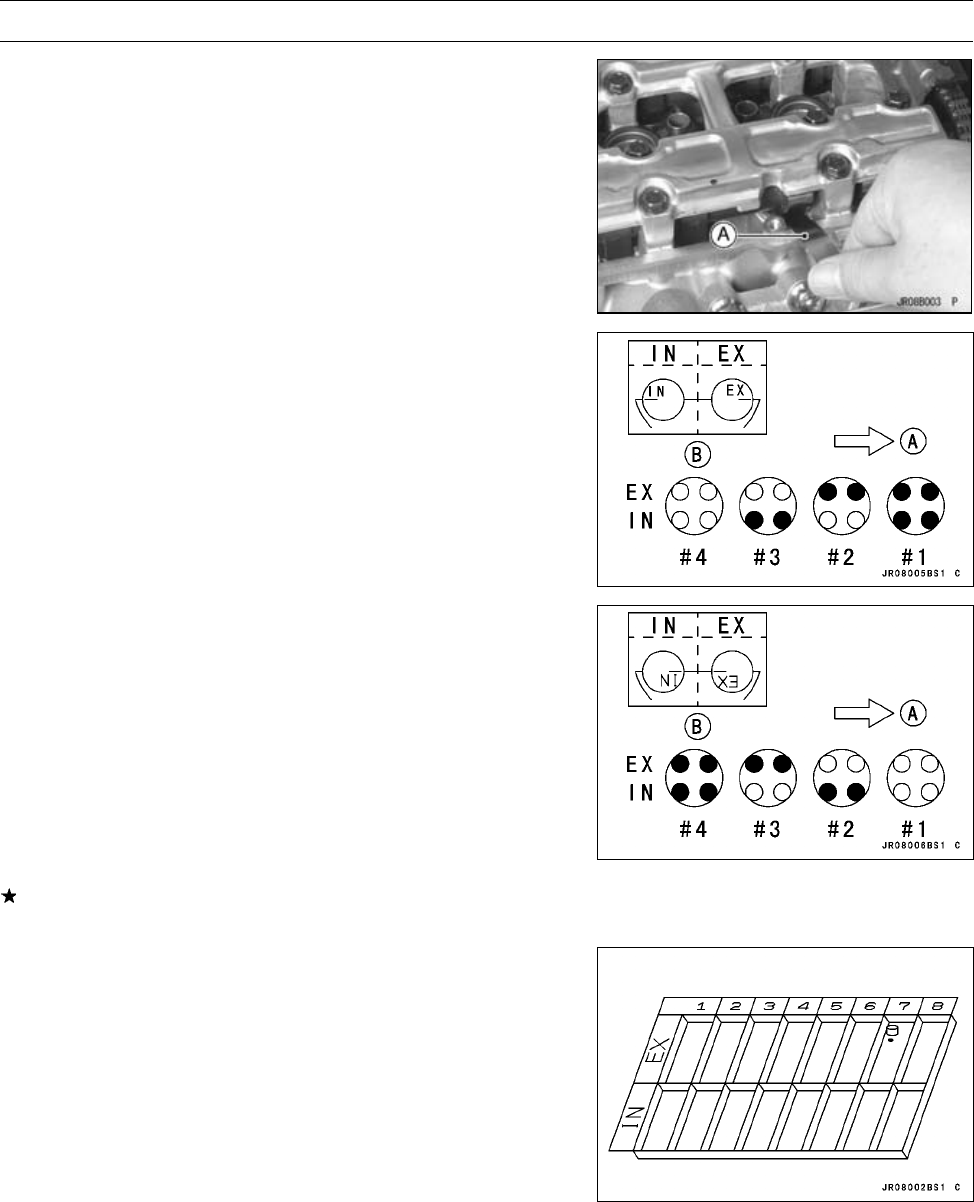

Measure the valve clearance between the cam and the

valve lifter with a thickness gauge [A].

Valve Clearance

Standard:

IN

0.15 ∼ 0.24 mm (0.0059 ∼ 0.0094 in.)

EX

0.22 ∼ 0.31 mm (0.0087 ∼ 0.0122 in.)

○

When positioning #1 piston TDC at the end of the

compression stroke:

Inlet Valve Clearance of #1 and #3 Cylinders

Exhaust Valve Clearance of #1 and #2 Cylinders

Measuring Valve [

•

]

Bow [A]

Camshaft Sprocket Position [B]

○

When positioning #4 piston TDC at the end of the

compression stroke:

Inlet Valve Clearance of #2 and #4 Cylinders

Exhaust Valve Clearance of #3 and #4 Cylinders

Measuring Valve [

•

]

Bow [A]

Camshaft Sprocket Position [B]

If the valve clearance is not within the specified range,

first record the clearance, and then adjust it.

•

To change the v alve clearance, remove the camshaft

chain tensioner, camshafts and valve lifters. Replace the

shim with one of a different thickness.

NOTE

○

Mark and record the valve lifter and shim locations so

they can be reinstalled in their original positions.

○

If there is no clearance, select a shim which is several

sizes smaller and then measure the clearance.

•

To select a new shim which brings the valve clearance

within the s pecified range, refer to the Valve Clearance

Adjustment Charts.