ENGINE BOTTOM END 8-23

Crankshaft and Connecting Rods

If any crankpin has worn past the service limit, replace the

crankshaft with a new one.

If the measured crankpin diameters are not less than the

service limit, but do not coincide with the original diameter

markings on the crankshaft, make new marks on it.

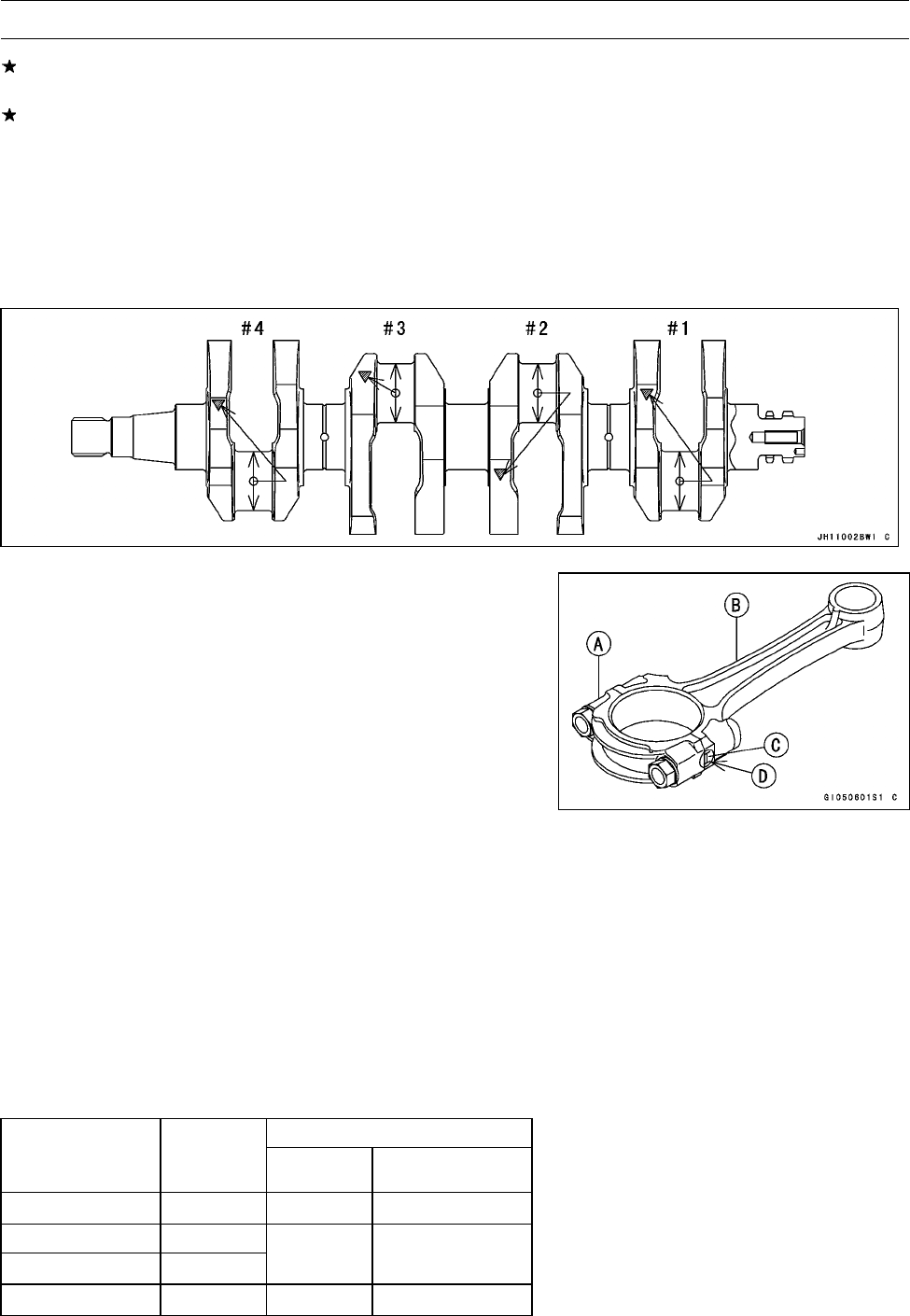

Crankpin Diameter Marks

None

38.984 ∼ 38.992 mm (1.5348 ∼ 1.5351 in.)

○

38.993 ∼ 39.000 mm (1.5352 ∼ 1.5354 in.)

∆: C rankpin Diameter Marks, “

○

” mark or no mark.

•

Measure the connecting rod big end bore diameter, and

mark each connecting rod big end in accordance with the

bore diameter.

BigEndCap[A]

Connecting Rod [B]

Weight Mark [C]: A letter of the alphabet

Bore Diameter Mark (Around Weight Mark) [D]: “

○

”or

no mark.

NOTE

○

Tighten the connecting rod big end nuts to the specified

torque (see Connecting Rod Installation).

○

The mark already on the big end should almost coincide

with the measurement.

Connecting Rod Big End Bore Diameter Marks

None

42.000 mm ∼ 42.008 mm (1.6535 ∼ 1.65386 in.)

○

42.009 ∼ 42.016 mm (1.65389 ∼ 1.6542 in.)

•

Select the proper bearing insert in accordance with the

combination coding of the connecting rod and crankshaft.

•

Install the new inserts in the connecting rod and check

insert/crankpin clearance with the plastigage.

Bearing Insert

Con-rod Big End

Bore Diameter

Marking

Crankpin

Diameter

Marking

Size Color Part Number

None

○

Brown 92139-3710

None None

○ ○

Black 92139-3709

○

None Blue 92139-3708