FUEL SYSTEM (DFI) 3-51

Fuel Injectors (Service Code/Character-41, 42, 43, 44/InJ1, InJ2, InJ3, InJ4)

Injector Fuel Line Inspection

•

Check the injector fuel line for leakage as follows:

○

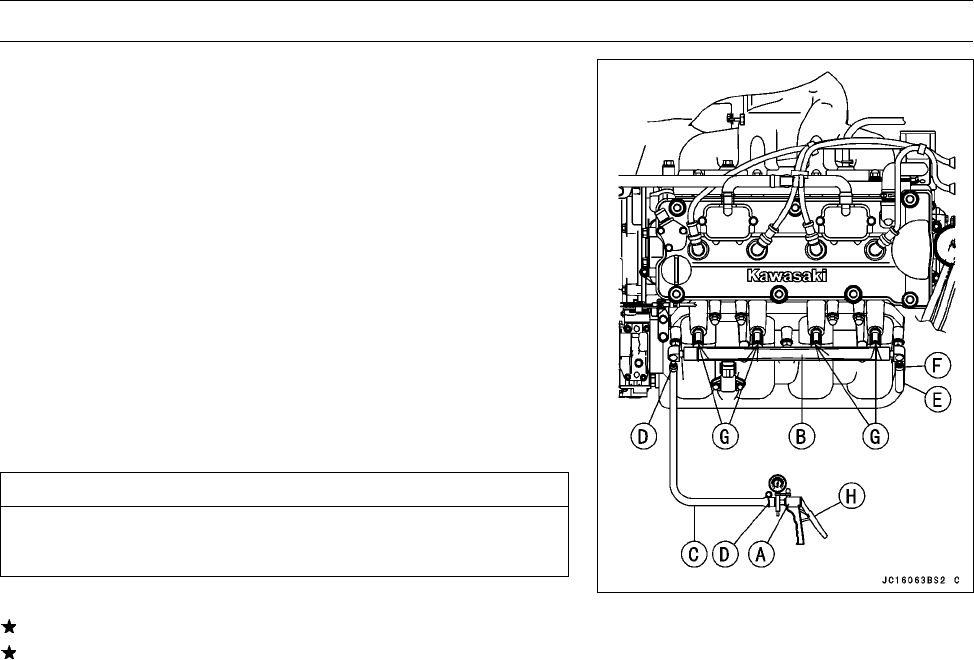

Connect a commercially available vacuum/pressure

pump [A] to the supply joint of the delivery pipe [B] with

the fuel hose [C] (both ends connected with the clamps

[D]) as shown.

○

Plug the return joint of the delivery pipe with a rubber plug

[E].

○

Tighten the clamp [F].

○

Apply soap and water solution to the areas [G] as shown.

○

Watching the pressure gauge, squeeze the pump lever

[H], and build up the pressure until the pressure reaches

the maximum pressure.

Fuel Line Maximum Pressure

Standard: 300 kPa (3.06 kgf/cm², 44 psi)

CAUTION

During pressure testing, do not exceed the maxi-

mum pressure for which the system is designed.

○

Watch the gauge for at least 6 seconds.

If the pressure holds steady, the system is good.

If the pressure drops at once, or if bubbles are found in

the area, the line is leaking. Replace the delivery pipe,

injectors and related parts.

•

Repeat the leak test, and check the fuel line for no leak-

age.

•

Run the hoses correctly (see Cable, Wire, and Hose Rout-

ing section in Appendix chapter).

○

For JT1500-A2 model ∼; Replace the double spring

clamps with new ones. (see Fuel System Diagram)