108

Speed control by Real sensorless vector

control, vector control

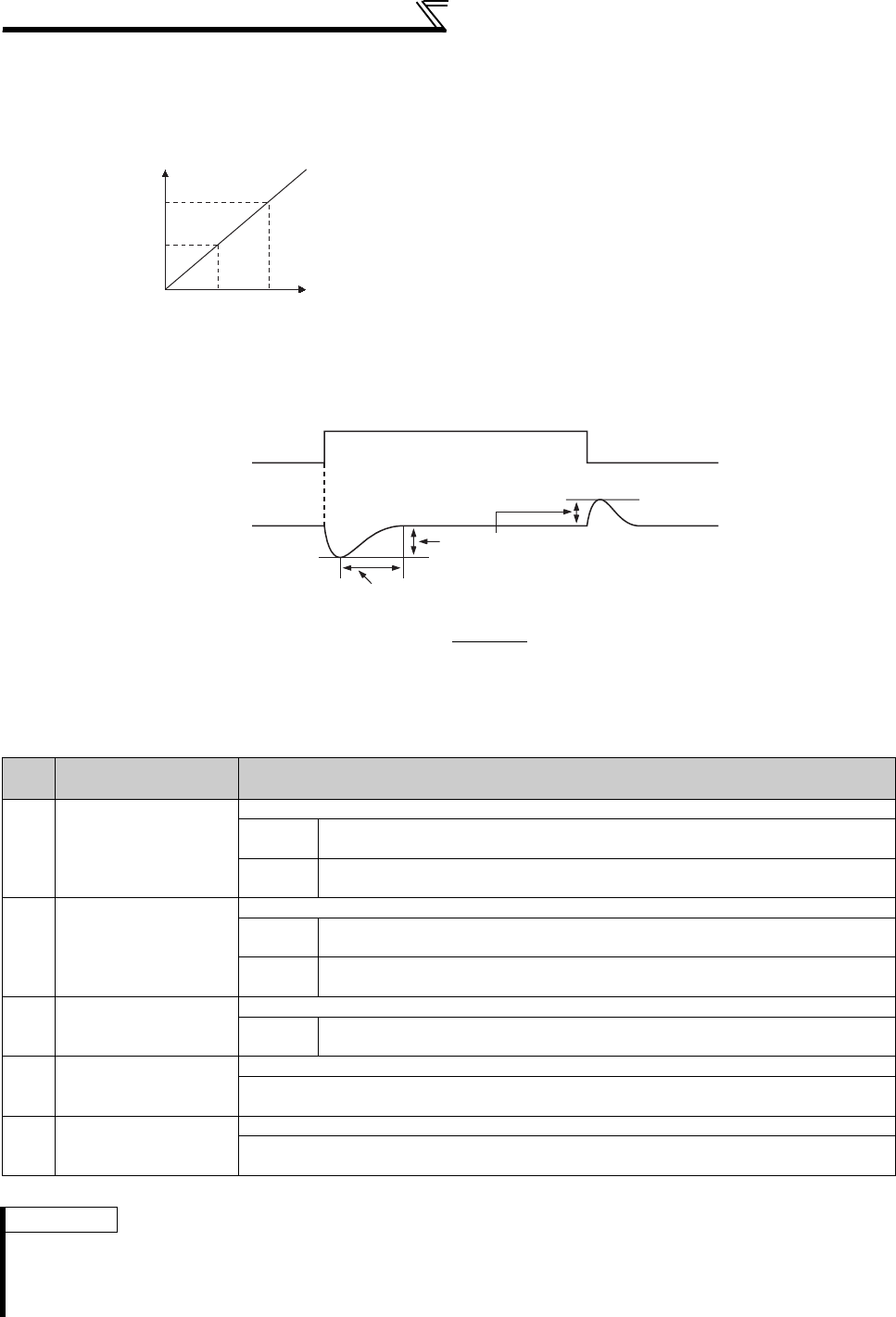

(5) Manual input speed control gain adjustment

· Make adjustment when any of such phenomena as unusual machine vibration/noise, low response level and

overshoot has occurred.

· When there is load inertia, the actual speed gain is as given below.

· Adjustment procedures are as below:

1)Check the conditions and simultaneously change the Pr. 820 value.

2)If you cannot make proper adjustment, change the Pr. 821 value and repeat step 1).

· Pr. 820 Speed control P gain 1 = "60%" (initial value) is equivalent to

120rad/s (speed response of the motor alone). (Half the value for

75K or higher or for Real sensorless vector control.) Increasing the

setting value improves the response level, but a too large gain will

produce vibration and/or unusual noise.

· Decreasing the Pr. 821 Speed control integral time 1 shortens the

return time taken at a speed change. However, a too short time will

generate an overshoot.

Actual speed gain = speed gain of motor without load ×

JM

JM: Inertia of the motor

JL: Motor shaft-equivalent load inertia

JM+JL

No.

Phenomenon/

Condition

Adjustment Method

1

Load inertia

is large

Set the Pr. 820 and Pr. 821 values a little higher.

Pr. 820

When a speed rise is slow, increase the value 10% by 10% until just before

vibration/noise is produced, and set about 0.8 to 0.9 of that value.

Pr. 821

If an overshoot occurs, double the value until an overshoot does not occur, and

set about 0.8 to 0.9 of that value.

2

Vibration/noise

generated from

mechanical system

Set the Pr. 820 value a little lower and the Pr. 821 value a little higher.

Pr. 820

Decrease the value 10% by 10% until just before vibration/noise is not produced,

and set about 0.8 to 0.9 of that value.

Pr. 821

If an overshoot occurs, double the value until an overshoot does not occur, and

set about 0.8 to 0.9 of that value.

3 Slow response

Set the Pr. 820 value a little higher.

Pr. 820

When a speed rise is slow, increase the value 5% by 5% until just before

vibration/noise is produced, and set about 0.8 to 0.9 of that value.

4

Long return time

(response time)

Set the Pr. 821 value a little lower.

Decrease the Pr. 821 value by half until just before an overshoot or the unstable phenomenon

does not occur, and set about 0.8 to 0.9 of that value.

5

Overshoot

or unstable

phenomenon occurs.

Set the Pr. 821 value a little higher.

Increase the Pr. 821 value double by double until just before an overshoot or the unstable

phenomenon does not occur, and set about 0.8 to 0.9 of that value.

REMARKS

· When making manual input gain adjustment, set "0" (without easy gain tuning) (initial value) in Pr. 819 Easy gain tuning

selection

.

· Pr. 830 Speed control P gain 2 and Pr. 831 Speed control integral time 2 are valid when the RT terminal is switched ON. Make

adjustments in the same way as Pr. 820 and Pr. 821.

Pr.820

Setting

100%

60%

(initial value)

Proportional gain

200 (100)rad/s*

120 (60)rad/s*

* The values for 75K or higher or for Real sensorless

vector control are indicated in parentheses.

Since increasing the proportional gain enhances the

response level and decreases the speed fluctuation.

Load

fluctuation

Speed

Decreasing the integral time shortens the return time taken.