177

Setting of acceleration/deceleration time

and acceleration/deceleration pattern

4

PARAMETERS

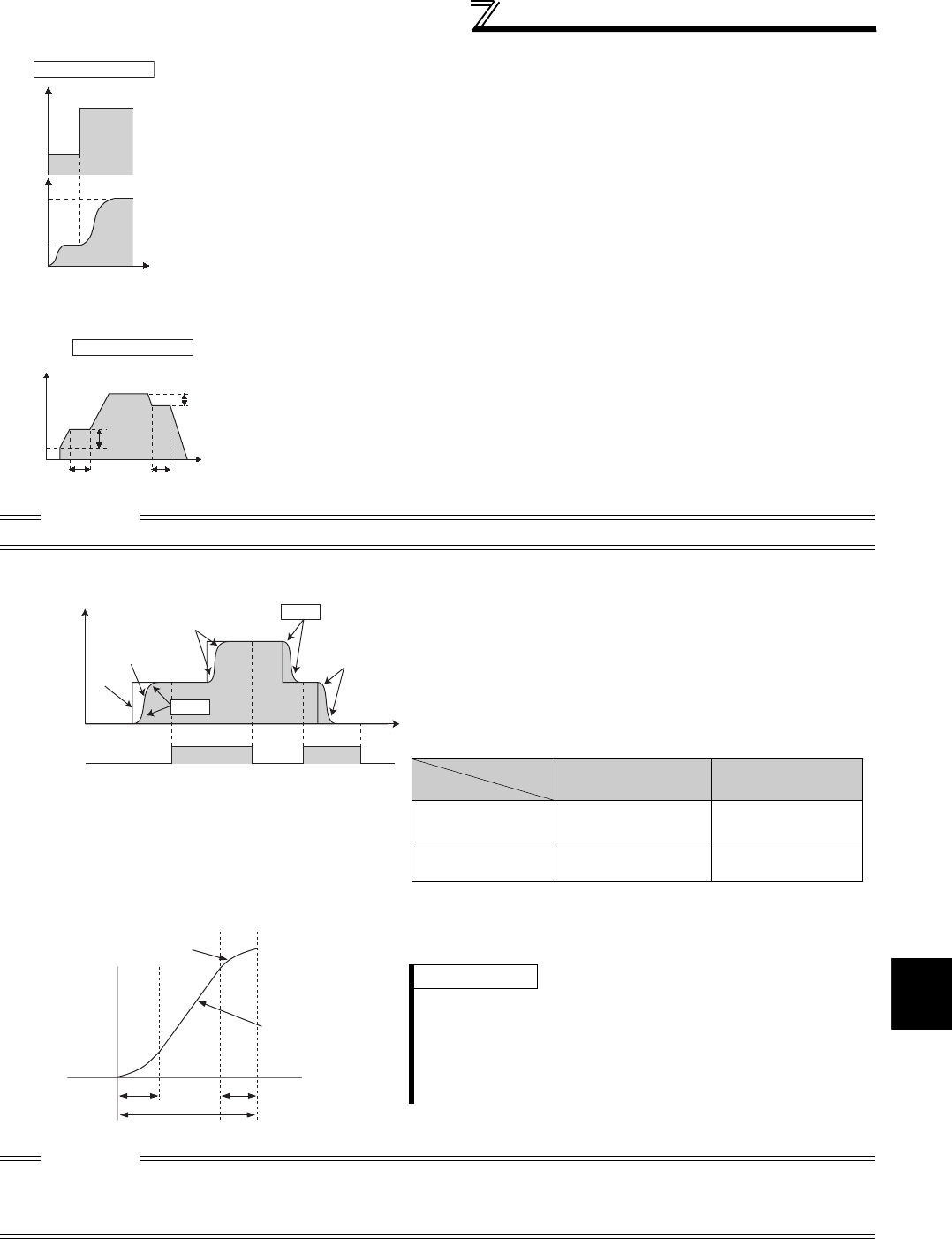

(3) S-pattern acceleration/deceleration B (

Pr. 29

=

"2")

⋅ For prevention of load shifting in conveyor and other applications

Since acceleration/deceleration is always made in an S shape from current

frequency (f2) to target frequency (f1), this function eases shock produced at

acceleration/deceleration and is effective for load collapse prevention, etc.

(4) Backlash measures (

Pr. 29

=

"3", Pr. 140 to Pr. 143)

⋅ What is backlash?

Reduction gears have an engagement gap and have a dead zone between

forward rotation and reverse rotation. This dead zone is called backlash, and

this gap disables a mechanical system from following motor rotation.

More specifically, a motor shaft develops excessive torque when the direction of

rotation changes or when constant-speed operation shifts to deceleration,

resulting in a sudden motor current increase or regenerative status.

⋅ To avoid backlash, acceleration/deceleration is temporarily stopped.

Set the acceleration/deceleration stopping frequency and time in Pr. 140 to Pr.

143.

CAUTION

Setting the backlash measures increases the acceleration/deceleration time by the stopping time.

(5) S-pattern acceleration/deceleration C (Pr. 29 =

"4", Pr. 380 to Pr. 383)

⋅ With the S-pattern acceleration/deceleration C switch

signal (X20), an acceleration/deceleration curve S-pattern 1

or S-pattern 2 can be selected.

⋅ For the terminal used for X20 signal input, set "20" in any of

Pr. 178 to Pr. 189 (input terminal function selection) to assign

the function.

Parameter setting (%) Ts / T

× 100%

⋅ Set % of time taken for forming an S-pattern in

Pr. 380 to Pr.

383

as acceleration time is 100%.

CAUTION

⋅ Change the S pattern acceleration/deceleration C switch (X20 signal) after the speed becomes constant.

⋅ S pattern operation before switching continues even if the X20 signal is changed during acceleration or deceleration.

⋅ The X20 signal can be assigned to the input terminal using any of Pr. 178 to Pr. 189 (input terminal function selection). Changing

the terminal assignment may affect the other functions. Set parameters after confirming the function of each terminal.

f1

Setting value "2"

[S-pattern acceleration

/deceleration B]

f2

Time

Set frequency

(Hz)

Output frequency

(Hz)

Pr. 142

Pr. 143

Pr. 141

Pr. 140

P

r. 13

Output frequency (Hz)

[Anti-backlash measure

function]

Setting value "3"

Time

Pr.382

Pr.383

Pr.381

S-pattern

acceleration/

deceleration

C switchover

(X20)

OFF

OFF

ON

Output frequency

Output frequency

Output frequency

Set frequency

Set frequency

Set frequency

Pr.380

Frequency

Tim

e

Operation

X20 signal

During

Acceleration

During

Deceleration

OFF

Pr. 380 Acceleration S-

pattern 1

Pr. 381 Deceleration

S-pattern 1

ON

Pr. 382 Acceleration S-

pattern 2

Pr. 383 Deceleration

S-pattern 2

S-pattern

acceleration

Linear

acceleration

Ts

T

Ts

REMARKS

⋅ At a start, the motor starts at Pr. 13 Starting frequency when the

start signal turns ON.

⋅ If there is a difference between the speed command and speed

at a start of deceleration due to torque limit operation etc., the

speed command is matched with the speed to make

deceleration.