382

Special operation and frequency control

(2) Selection of encoder feedback control (Pr. 367 )

(3) Feedback gain (Pr. 368 )

⋅ Set Pr. 368 Feedback gain when the rotation is unstable or response is slow.

⋅ If the acceleration/deceleration time is long, feedback response becomes slower. In this case, increase the Pr. 368

setting.

⋅

(4) Overspeed detection (Pr. 285 )

⋅ If (detection frequency) - (output frequency) > Pr. 285 under encoder feedback control, E.MB1 occurs and the inverter

output is stopped to prevent malfunction when the accurate pulse signal from the encoder cannot be detected.

Overspeed is not detected when Pr. 285 = "9999".

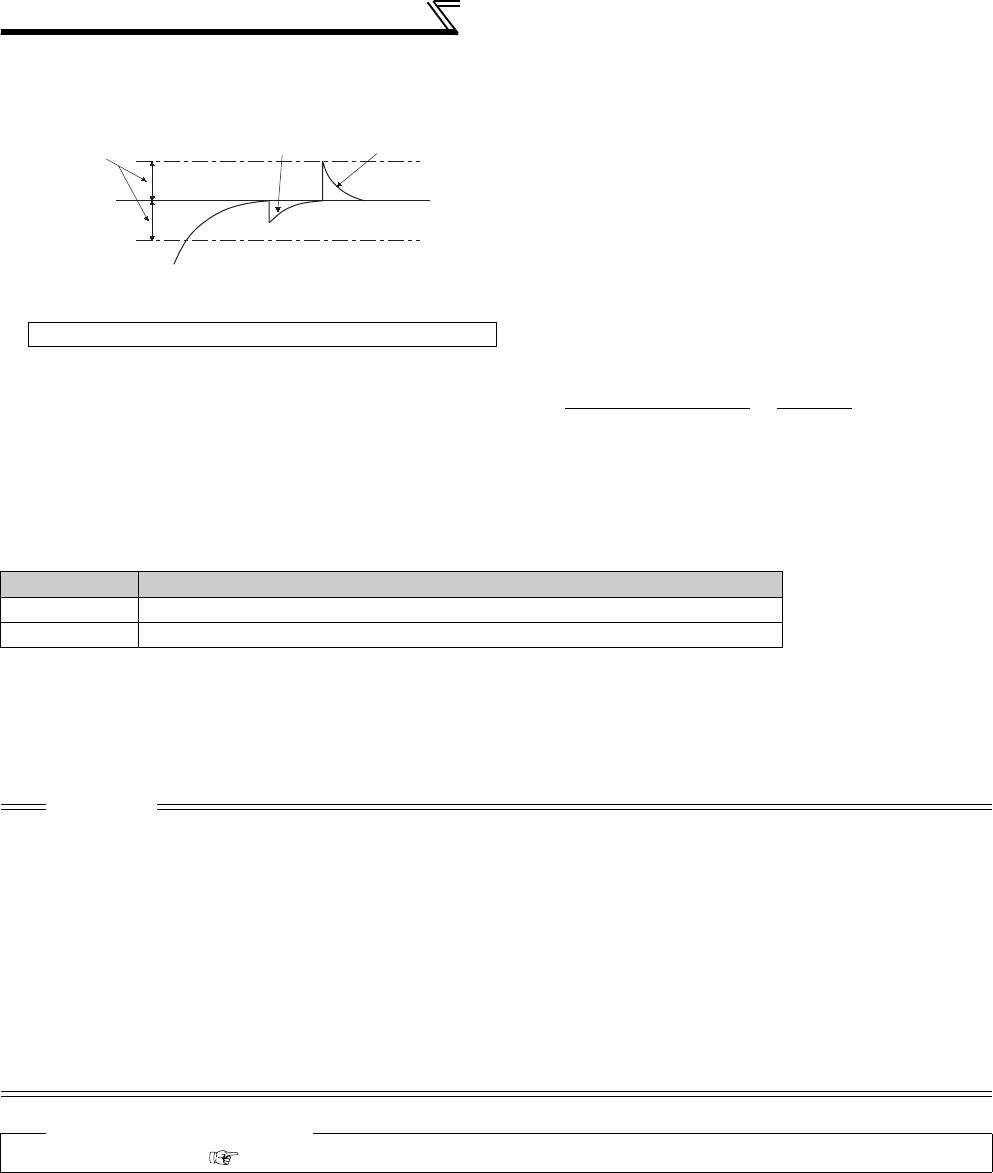

⋅ When a value other than "9999" is set in Pr. 367 Speed

feedback range, encoder feedback control is valid.

Using the set point (frequency at which stable speed

operation is performed) as reference, set the higher and

lower setting range. Normally, set the frequency

converted from the slip amount (r/min) of the rated motor

speed (rated load). If the setting is too large, response

becomes slow.

Example: Rated speed of a 4-pole motor is 1740r/min (60Hz)

Slip Nsp = Synchronous speed - Rated speed Frequency equivalent to slip (fsp)

= 1800 - 1740 = 60(r/min)

fsp =

Nsp × Number of poles

=

60 × 4

=2 (Hz)

120 120

Pr. 368 Setting Description

Pr. 368 > 1

Although the response becomes faster, overcurrent or unstable rotation is liable to occur.

1 < Pr. 368

Although the response becomes slower, the motor rotation becomes stable.

CAUTION

⋅ The encoder should be coupled on the same axis with the motor shaft without any mechanical looseness with a speed ratio of

1 to 1.

⋅ During acceleration/deceleration, encoder feedback control is not performed to prevent unstable phenomenon such as hunting.

⋅ Encoder feedback control is performed once output frequency has reached within [set frequency] ± [speed feedback range].

⋅ If the following conditions occur during encoder feedback control, the inverter operates at the frequency within [set speed] ±

[speed feedback range] without coming to trip nor tracking the motor speed.

⋅ The pulse signals are not received from the encoder due to a signal loss, etc.

⋅ The accurate pulse signal from the encoder cannot be detected due to induction noise, etc.

⋅ The motor has been forcibly accelerated (regeneration) or decelerated (motor lock or the like) by large external force.

⋅ For the motor with brake, use the RUN signal (inverter running) to open the brake. (The brake may not be opened if the FU

(output frequency detection) signal is used.)

⋅ Do not turn OFF the external power supply of the encoder during encoder feedback control. Encoder feedback control

functions abnormally.

♦ Parameters referred to ♦

Pr. 81 Number of motor poles Refer to page 148

Speed feedback range

Set value

(Set command)

Driven load

Regeneration load