214

Motor brake and stop operation

4.14.4 Stop-on contact control function (Pr. 6, Pr. 48, Pr. 270, Pr. 275, Pr. 276)

*1 This parameter allows its setting to be changed during operation in any operation mode even if "0 (initial value) or 1" is set in Pr. 77 Parameter write

selection.

*2 This parameter allows its setting to be changed during operation even if "0" (initial value) is set in Pr. 77 Parameter write selection.

.............Specifications differ according to the date assembled. Refer to page 484 to check the SERIAL number.

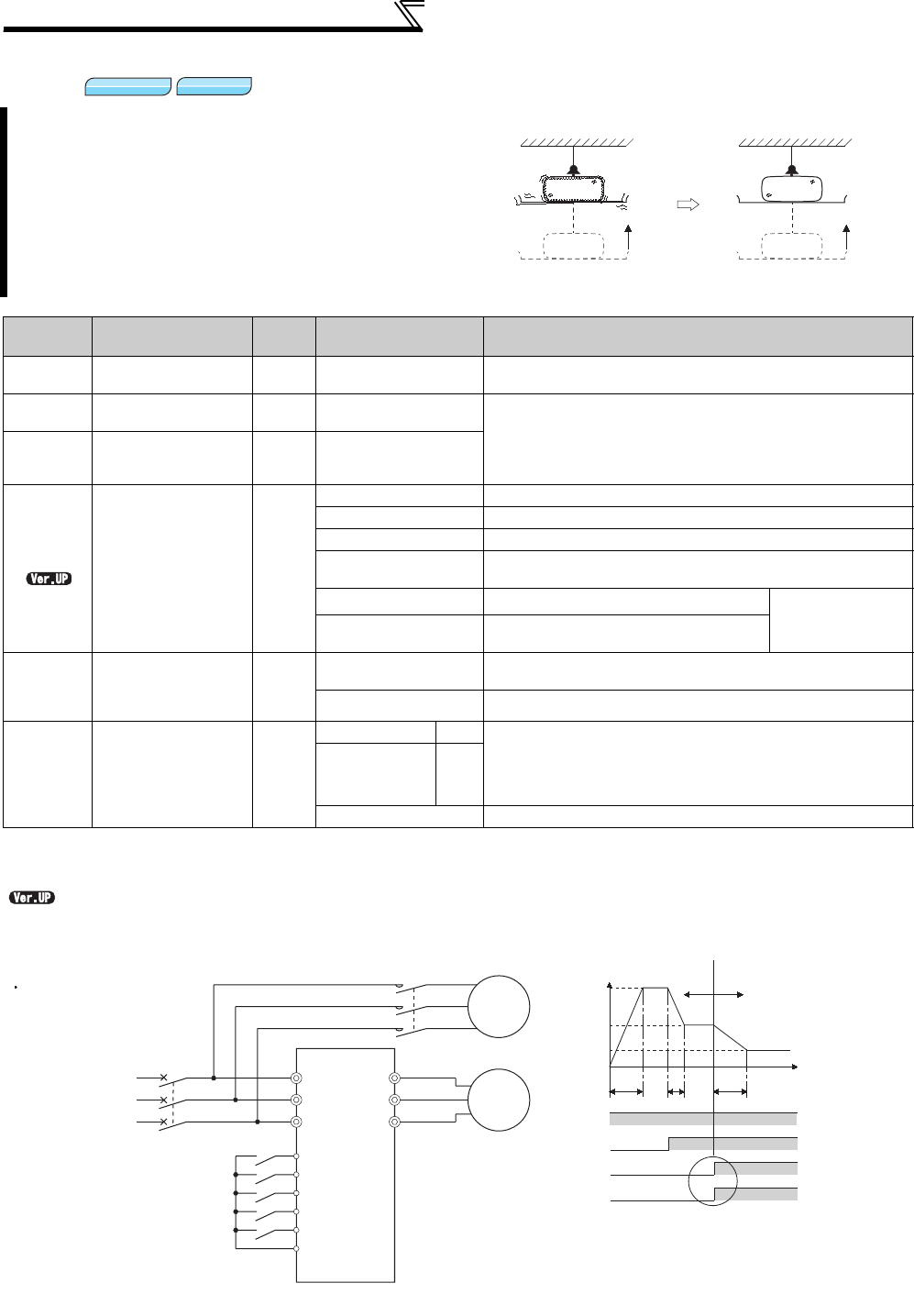

<Connection and operation example>

To ensure accurate positioning at the upper limit etc. of

a lift, stop-on-contact control causes a mechanical

brake to be closed while the motor is developing a

holding torque to keep the load in contact with a

mechanical stopper etc.

This function suppresses vibration which is liable to

occur when the load is stopped upon contact in vertical

motion applications, ensuring steady precise

positioning.

Parameter

Number

Name

Initial

Value

Setting Range Description

6

Multi-speed setting

(low speed)

10Hz 0 to 400Hz Set the output frequency for stop-on-contact control.

22

*1

Stall prevention

operation level

150% 0 to 400%

Set the stall prevention operation level for stop-on-contact

control.

The smaller value set in either Pr. 22 or Pr. 48 has a priority.

48

Second stall

prevention

operation current

150% 0 to 220%

270

Stop-on contact/

load torque high-

speed frequency

control selection

0

0 Normal operation

1 Stop-on-contact control

2 Load torque high speed frequency control (Refer to page 374)

3

Stop-on-contact+load torque high speed frequency control

(Refer to page 374)

11 Stop-on-contact control

E.OLT invalid under

stop-on-contact

control

13

Stop-on-contact+load torque high speed

frequency control (Refer to page 374)

275

*2

Stop-on contact

excitation current

low-speed

multiplying factor

9999

0 to 1000%

Set the force (holding torque) for stop-on-contact control.

Normally set 130% to 180%.

9999 No compensation.

276

PWM carrier

frequency at stop-

on contact

9999

55K or lower 0 to 9 Set a PWM carrier frequency for stop-on-contact control.

For Real sensorless vector control, carrier frequency is

always 2Hz when a setting value is 0 to 5 and always 6Hz

when a setting value is 6 to 9. (Valid at the frequency of 3Hz

or less.)

75K or higher 0 to 4

9999 As set in Pr. 72 PWM frequency selection .

Magnetic flux

Magnetic flux

Magnetic flux

Sensorless

Sensorless

Sensorless

<Without stop-on-contact control>

Vibration Complete stop

Lift Lift

<With stop-on-contact control>

Power

supply

Forward rotation command

High-speed operation command

Middle-speed operation command

Stop-on contact selection 0

Stop-on contact selection 1

MCCB

R/L1

S/L2

T/L3

STF

RH *

RM *

RL *

RT *

U

V

W

MC

Mechanical

brake

Motor

* The input terminal used differs according to the Pr. 180 to Pr. 189 settings.

SD

Sink logic

(a) (b) (c)

Time

Pr. 4

RH

RM

RL

RT

Pr. 5

Pr. 6

Output frequency

0

Normal mode

Stop-on contact

control mode

(a):Acceleration time (Pr. 7 )

(b):Deceleration time (Pr. 8 )

(c):Second deceleration time (Pr. 44/Pr. 45 )

*

ONOFF

ONOFF

ONOFF

ON

Goes into stop-on-contact control mode when

both RL and RT switch on.

*RL and RT may be switched on in any order

with any time difference