425

Check first when you have a trouble

5

PROTECTIVE FUNCTIONS

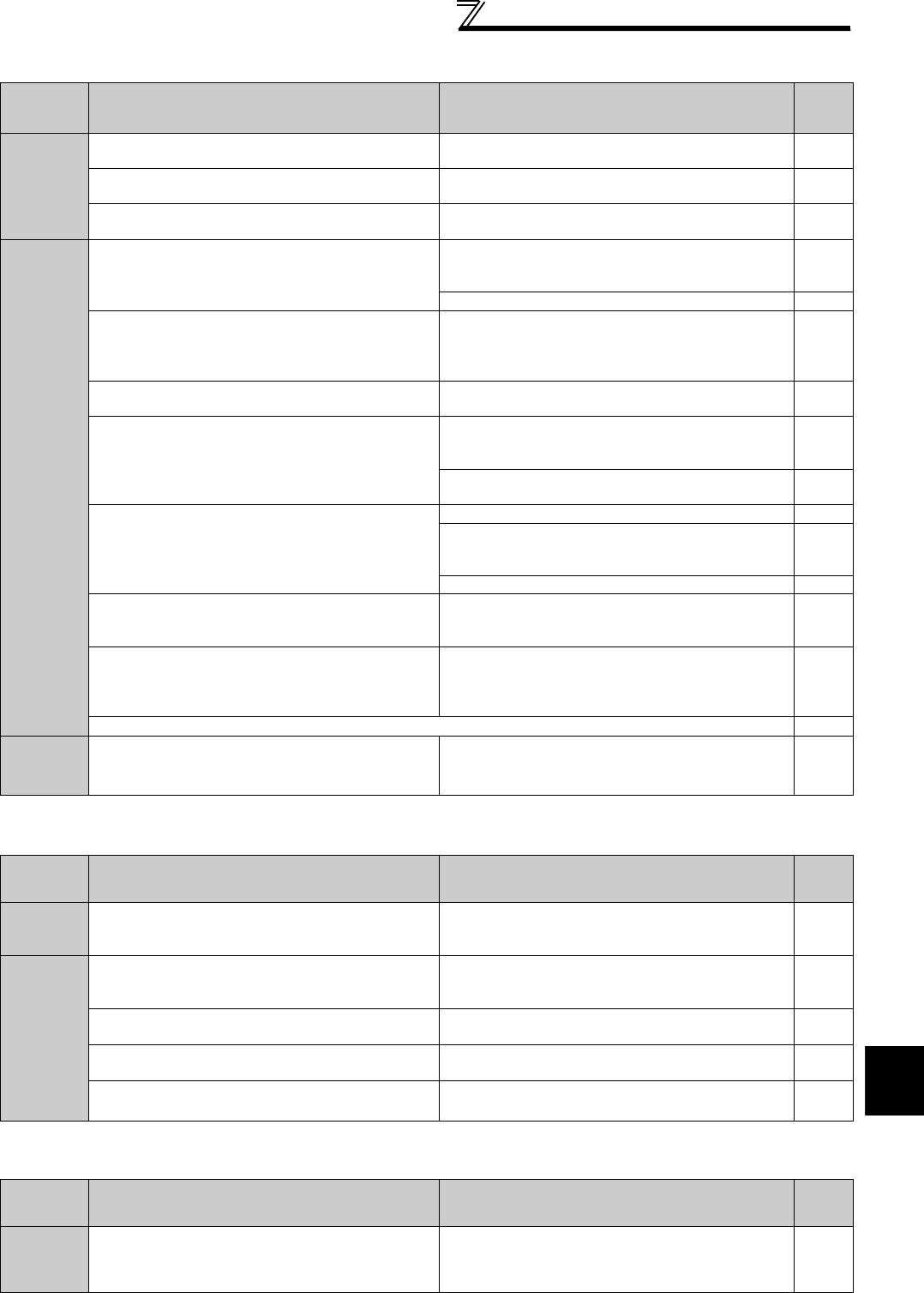

5.5.12 Speed does not accelerate

5.5.13 Unable to write parameter setting

5.5.14 Power lamp is not lit

Check

points

Possible Cause Countermeasures

Refer

to

page

Input

signal

Start command and frequency command are chattering.

Check if the start command and the frequency

command are correct.

—

The wiring length used for analog frequency command

is too long, and it is causing a voltage (current) drop.

Perform analog input bias/gain calibration.

294

Input signal lines are affected by external EMI.

Take countermeasures against EMI, such as using

shielded wires for input signal lines.

54

Parameter

Setting

Pr. 1, Pr. 2, Pr. 18, calibration parameter C2 to C7 settings

are improper.

Check the settings of Pr. 1 Maximum frequency and Pr. 2

Minimum frequency. If you want to run the motor at 120Hz

or higher, set Pr. 18 High speed maximum frequency.

157

Check the calibration parameter C2 to C7 settings. 294

The maximum voltage (current) input value is not set

during the external operation. (Pr.125, Pr.126, Pr.18)

Check the Pr.125 Terminal 2 frequency setting gain

frequency and Pr.126 Terminal 4 frequency setting gain

frequency settings. To operate at 120Hz or higher, set

Pr.18 High speed maximum frequency.

157,

294

Torque boost (

Pr. 0, Pr. 46, Pr. 112

) setting is improper under

V/F control, so the stall prevention function is activated.

Increase/decrease Pr. 0 Torque boost setting value by

0.5% increments so that stall prevention does not occur.

146

V/F pattern is improper when V/F control is performed.

(Pr. 3, Pr. 14, Pr. 19)

Set rated frequency of the motor to Pr. 3 Base frequency.

Use Pr. 19 Base frequency voltage to set the base

voltage (e.g. rated motor voltage).

159

Change Pr. 14 Load pattern selection according to the load

characteristic.

161

Stall prevention (torque limit) function is activated due to

a heavy load.

Reduce the load weight. —

Set Pr. 22 Stall prevention operation level (Torque limit level)

higher according to the load. (Setting Pr. 22 too large

may result in frequent overcurrent trip (E.OC).)

152

(100)

Check the capacities of the inverter and the motor. —

Auto tuning is not performed under Advanced magnetic

flux vector control, Real sensorless vector control, or

vector control.

Perform offline auto tuning. 189

The setting of pulse train input is improper.

Check the specification of the pulse generator (open

collector output or complementary output) and check the

adjustment of the pulse train and frequency (Pr. 385 and

Pr. 386).

378

During PID control, output frequency is automatically controlled to make measured value = set point.

361

Main

Circuit

Brake resistor is connected across terminals P/+ and

P1 or across P1 and PR by mistake. (22K or lower)

Remove the jumper across terminals PR and PX (7.5K

or lower) and connect an option brake resistor (FR-ABR)

across terminals P/+ and PR.

14

Check

points

Possible Cause Countermeasures

Refer

to

page

Input

signal

Operation is being performed (signal STF or STR is

ON).

Stop the operation.

When Pr. 77 = "0" (initial value), write is enabled only

during a stop.

307

Parameter

Setting

You are attempting to set the parameter in the External

operation mode.

Choose the PU operation mode.

Or, set Pr. 77 = "2" to enable parameter write regardless

of the operation mode.

307

Parameter is disabled by the Pr. 77 Parameter write

selection setting.

Check Pr. 77 Parameter write selection setting.

307

Key lock is activated by the Pr. 161 Frequency setting/key

lock operation selection setting.

Check Pr. 161 Frequency setting/key lock operation selection

setting.

393

Operation mode and a writing device do not

correspond.

Check Pr. 79, Pr. 338, Pr. 339, Pr. 550, Pr. 551, and select

an operation mode suitable for the purpose.

313,

322

Check

points

Possible Cause Countermeasures

Refer

to

page

Main

Circuit,

Control

Circuit

Wiring or installation is improper.

Check for the wiring and the installation.

Power lamp is lit when power is input to the control

circuit (R1/L11, S1/L21).

16