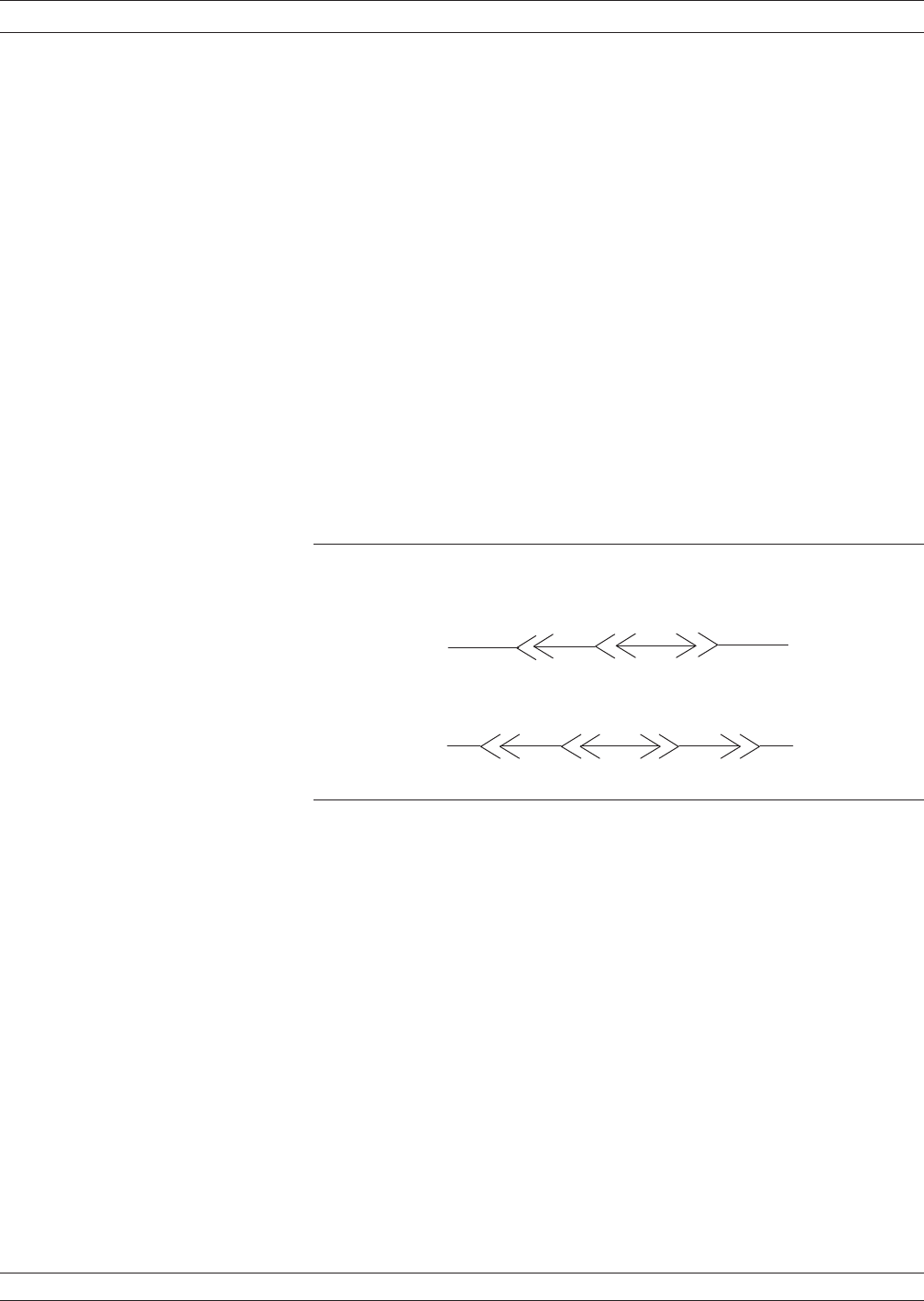

This approach offers two advantages:

q

It minimizes wear on the more expensive test set and cable con

-

nectors

q

It provides a simple solution to measuring non-insertable devices

(e.g., a filter with K female input and output connectors) by

merely swapping PEAs after calibration. See Figure 7-4

NOTE

In this and other discussions, we will talk about

“insertable” and “non-insertable” devices. Insertable de

-

vices have an insertable connector pair (i.e., male input

and female output connectors) and can be measured after

a through calibration. A non-insertable device has a

non-insertable pair of connectors. This would be the case if

it included female connectors on both ports or different

connector types on each port. Therefore, “non-insertables”

cannot be connected directly into the measurement path

without an adapter.

Understanding the

Calibration System

Measurement errors must be reduced by a process that uses calibra

-

tion standards. The standards most commonly used are Opens, Shorts,

and Z

0

(Characteristic Impedance) Loads. In conjunction with a

through connection, these standards can correct for the major errors in

a microwave test system. These errors are Directivity, Source Match,

Load Match, Isolation, and Frequency Tracking (reflection and trans

-

mission).

Calibration also corrects for many internal system errors, such as RF

leakage, IF leakage, and system component interaction.

Random errors such as noise, temperature, connector repeatability,

DUT sensitive leakages, frequency repeatability, and calibration vari

-

ables are not completely correctable. However, some of them can be

minimized by careful control. For instance: temperature effects can be

reduced by room temperature control, calibration variables can be re

-

37xxxE OM 7-5

MEASUREMENT CALIBRATION DISCUSSION

Calibration

Measurement

MF

PEA

USING THE PHASE-EQUAL INSERTABLE

(PEI)

F

MF

MFMF MFMF

DUT

TEST

PORT

TEST

PORT

TEST

PORT

TEST

PORT

PEA

PEA

PEA

M

Figure 7-4. Using Phase-Equal Insertables